1, the problem of motor efficiency and temperature rise

No matter what type of frequency converter, will produce different degrees of harmonic voltage and current in operation, so that the motor running in non-sinusoidal voltage and current.

If the ordinary three-phase asynchronous motor running in the output of the inverter non-sinusoidal power conditions, the temperature rise generally increase 10% to 20%.

2, motor insulation strength problem

At present small and medium-sized frequency converter, many adopt PWM control mode.

Its carrier frequency is about a few thousand to a dozen kilohertz, which makes the motor stator windings to withstand high voltage rise rate, equivalent to the imposition of a steep motor surge voltage, the motor turns to withstand more insulation Harsh test.

In addition, the PWM chopper generated by the rectangular chopper impulse voltage superimposed on the motor operating voltage, the motor will pose a threat to the insulation, insulation to high voltage repeated impact will accelerate the aging.

3, harmonic electromagnetic noise and vibration

Ordinary asynchronous motor inverter power supply, will make the electromagnetic, mechanical, ventilation and other factors caused by the vibration and noise become more complex.

4, the motor on the frequent start, brake adaptability

As a result of inverter power supply, the motor can be started at low frequency and voltage with no rush current, and can be quickly braked by various braking methods provided by the inverter. In order to achieve frequent starting and braking Created the condition that the mechanical system and the electromagnetism system of the motor are under cyclic alternating force, which brings fatigue and accelerated aging problems to the mechanical structure and the insulation structure.

5, low-speed cooling problems

Asynchronous motor impedance is not ideal, when the power frequency is low, the power caused by high harmonics greater loss.

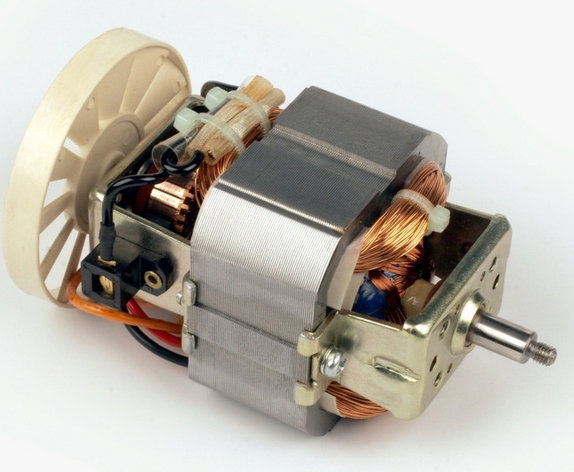

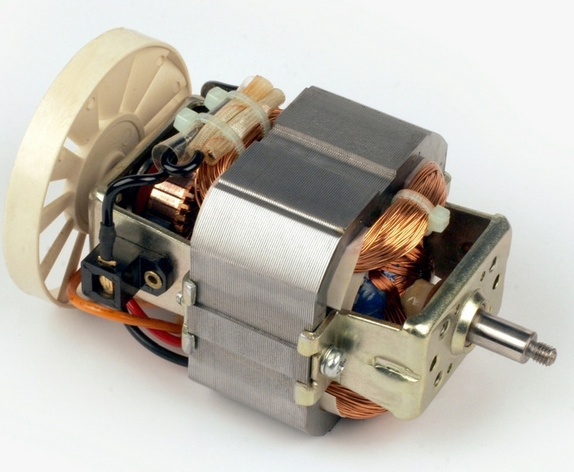

Inverter motor characteristics

1, electromagnetic design

For general asynchronous motors, the main performance parameters considered at design time are overload capacity, starting performance, efficiency and power factor.

The inverter motor, as the critical slip ratio is inversely proportional to the power frequency, the critical slip can be close to 1 direct start, therefore, overload and starting performance no longer need to be considered too much, but the key issue to be solved is how to improve the motor Adaptability to non-sinusoidal power supplies.

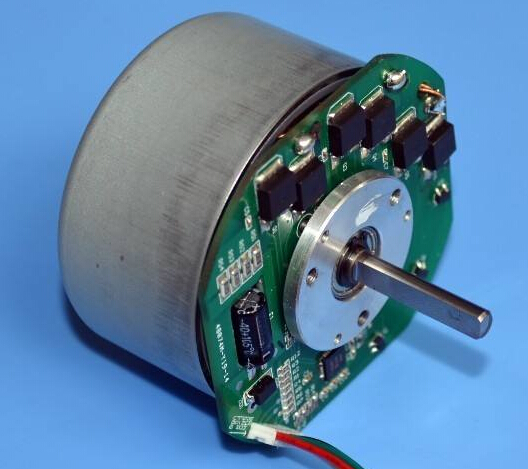

2, structural design

In structural design, the main consideration is the influence of non-sinusoidal power supply characteristics on the insulation structure, vibration and noise cooling of the inverter motor. General attention to the following questions:

Insulation level, generally F-class or higher, to strengthen the ground insulation and turn insulation strength, in particular, to consider the impact of insulation resistance to voltage capability.

RCCN WeChat QrCode

RCCN WeChat QrCode Mobile WebSite

Mobile WebSite