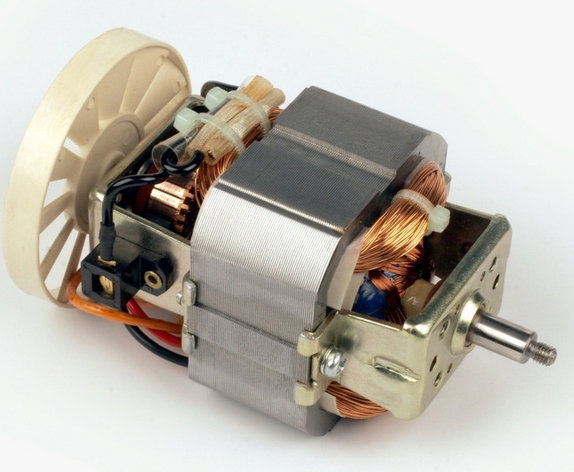

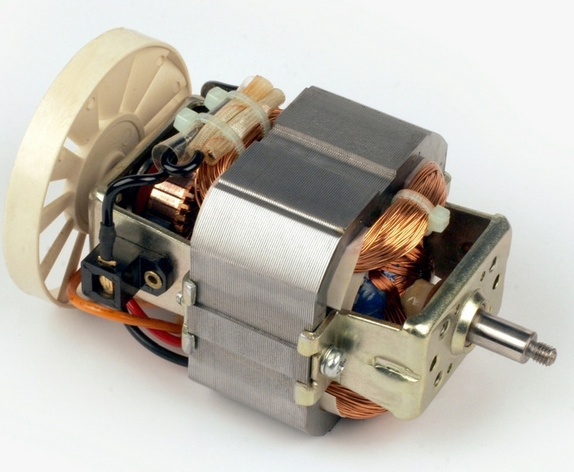

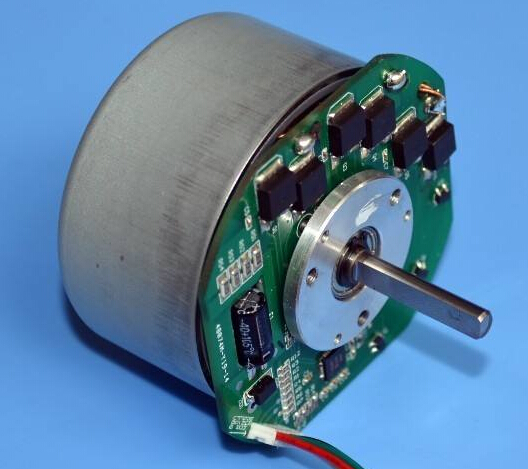

DC motor failure and more concentrated in the brush, commutator, bearings and other components. These three locations are the most likely locations to fail.

Then we come to understand how to under the DC motor maintenance and repair.

1, the commutator maintenance:

Commutator DC motor is a very important part, this part is one of the main motor failure. One of the most difficult to deal with is the commutator this one, commutator working conditions directly related to the work of the DC motor, it is necessary to strengthen the commutator maintenance.

The commutator's main fault is the commutation spark, in order to allow the motor to run better we must keep the commutator surface clean, to be regularly cleaned. If commutator surface with slight stripes or grooves. At this point you can polish or polish the commutator, and then clean the commutator surface with a clean silk cloth, which helps to form an oxide film to protect the commutator.

2, brush maintenance and repair

3, bearing maintenance

RCCN WeChat QrCode

RCCN WeChat QrCode Mobile WebSite

Mobile WebSite