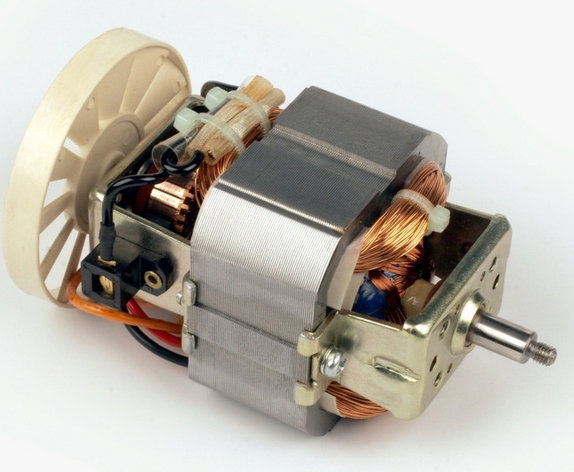

DC motor fault and more concentrated in the brush, commutator, bearings and other components. These three are the most likely to fail.

Then let's take a look at how to maintain and maintain the DC motor.

1, commutator maintenance:

The commutator is a very important part of the DC gear motor, which is also one of the major causes of motor failure. One of the most difficult to deal with is the commutator of this one, commutator working conditions directly related to the working conditions of DC motor, it must strengthen the commutator maintenance.

The main failure of the commutator is in the exchange of sparks, in order to allow the motor to run better we must keep the commutator surface clean, to do regular cleaning. If the commutator surface has a slight stripes or grooves. Then the commutator can be polished or polished, and then use a clean silk cloth wipe the commutator surface, which is conducive to the formation of oxide film protection commutator.

2, brush maintenance and maintenance

(1) to confirm the brush braided screws are fastened, brush braids do not affect the brush of the free movement:

(2) to ensure that you do not touch the brush braids within the motor non-insulator

(3) check whether the brush can move freely in the brush grip, the spring position must be accurate, functional

(4) brush away from the commutator surface distance should be consistent

(5) The replacement of the carbon brush should be suitable for the commutator surface curve

RCCN WeChat QrCode

RCCN WeChat QrCode Mobile WebSite

Mobile WebSite