First, the principle of motor and controller

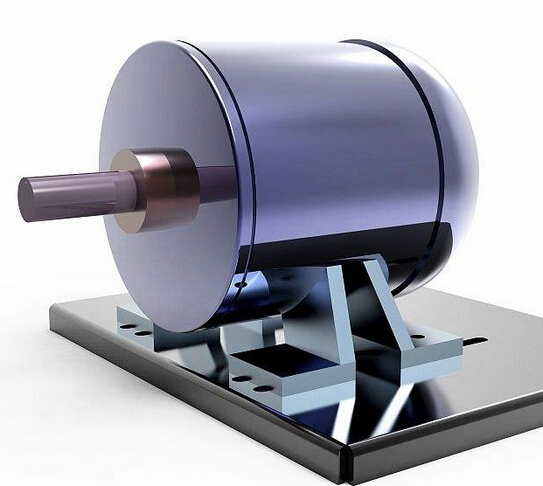

The principle of the motor and the controller is shown in Fig. The motor drives the car forward, while the motor controller drives the motor to work. The motor controller consists of two parts: inverter and controller. The inverter receives the battery from the DC power supply, reverse into three-phase AC power to the car motor. The controller receives the motor speed and other signals back to the instrument, when the braking or acceleration behavior occurs, the controller controls the frequency of the inverter movements, so as to achieve the purpose of acceleration or deceleration.

Figure 1 motor and controller principle

Second, the motor control drive system classification

Electric vehicle load is a random change, the specific performance of the vehicle driving direction and forward, with acceleration and deceleration. The basic function of the motor control drive system is to control the motor work, to ensure that the car forward and backward, acceleration and deceleration freely. Basic classification:

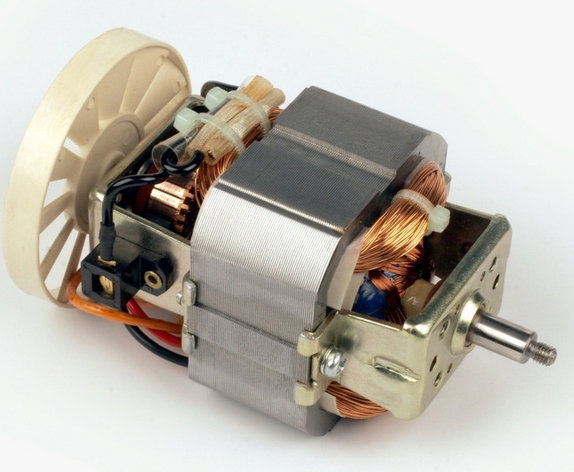

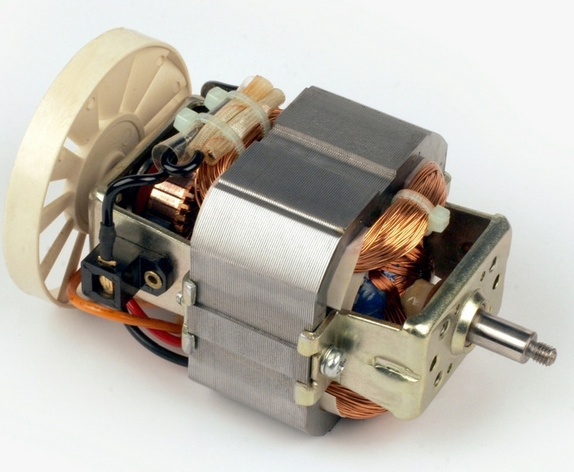

① DC motor drive system: the general use of pulse width modulation (PWM) chopper control mode, which is characterized by simple control technology, mature, low cost, but low efficiency, large size and so on.

② AC induction motor drive system: the general use of pulse width modulation (PWM) chopper control, high voltage DC to three-phase AC power conversion, the use of frequency control mode to achieve motor speed, the use of vector control or direct torque control strategy Fast response of motor torque control.

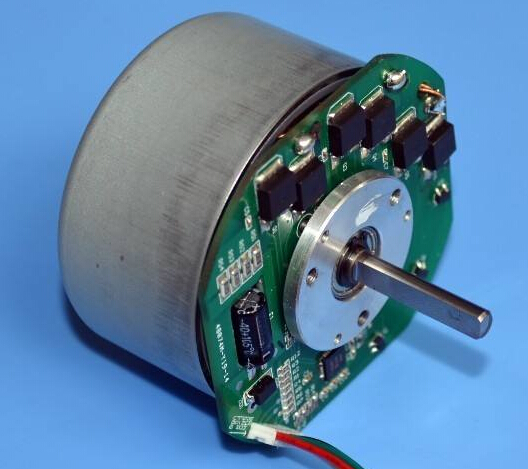

③ AC permanent magnet motor drive system: the current mainstream is the use of PWM way to achieve high-voltage DC to three-phase AC power conversion, the use of frequency control mode to achieve motor speed, low speed torque ripple and high speed constant power zone speed stable.

At present, most of the pure electric vehicles with permanent magnet synchronous motor, the use of rare earth permanent magnet excitation, compared with the induction motor does not require excitation circuit, with high efficiency, power density, high control accuracy, torque ripple and so on.

Third, the basic trend of electric vehicle motor controller is integrated

At present, urban motor vehicle motor controller has been "five in one" level, on behalf of the development direction. There are five major categories of products:

① single master controller, auxiliary three-in-one controller (integrated: EHPS controller + ACM controller + DCDC);

② auxiliary five-in-one controller (integrated: EHPS controller + ACM controller + DCDC + PDU + dual source EPS controller);

③ passenger car controller (integrated: main drive + DCDC);

④ vehicle three-in-one controller (integrated: main drive + DCDC + PDU);

⑤ logistics car five in one controller (integrated: main drive + EHPS controller + ACM controller + DCDC + PDU).

Four, all-in-one motor controller function introduction

① basic functions: through the inverter bridge modulation output is positive to drive the motor;

② distribution circuit: the integration of other parts of the controller to provide power distribution, such as TM contactors, fuses, electrical air conditioning circuit power supply, electric defrost circuit power supply and so on;

③IGBT drive circuit: receive control signals, drive IGBT and feedback state, to provide voltage isolation and protection;

④ auxiliary power supply: the control circuit to provide power for the drive circuit to provide isolated power supply;

⑤ DSP circuit: to receive vehicle control instructions, and provide feedback information to detect the motor system sensor information, according to the instruction transmission motor control signal;

⑥ structure and cooling system: for the motor controller to provide cooling, to provide controller installation support, to provide controller security protection.

Fifth, electric vehicle motor controller technology development trend

① high security, this is the basic requirements. More and more integrated features, the higher the security requirements.

② high power density. Shape volume with the sub-installed to the miniaturization of the development.

③ high pressure is the basic trend. GBT direction is 650V IGBT design to higher 750V and 1200V.

④EMC level is getting higher and higher. Next to do class5 level.

Six Summary

The development of electric vehicles, electronic control part of the technical content is very high, especially the motor controller, China's current controller in the integration of progress is quite fast, but the key electronic devices (such as IGBT) mainly rely on foreign provide.

RCCN WeChat QrCode

RCCN WeChat QrCode Mobile WebSite

Mobile WebSite