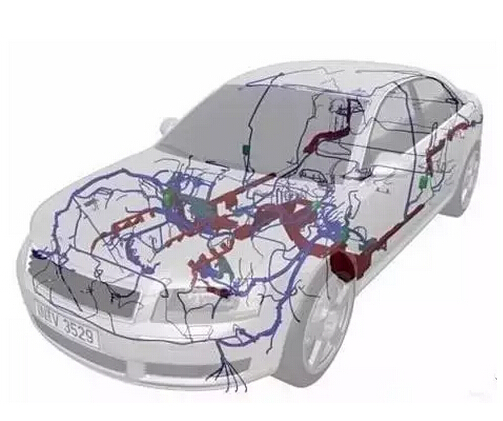

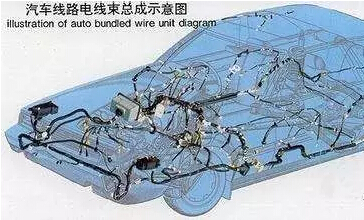

In order to ensure the safety and reliability of the wiring harness, strict process screening and supplementary screening must be carried out on the product line standard or before the user uses it. In order to promptly identify and reject defective products (breaking, short-circuit), poor insulation (short circuit) and assembly errors (miswiring) and other unqualified failure products. However, at present, many units are still lagging behind in the production or use of on-site inspection harness harnesses. Some of the military harnesses used for key models are still using manual meters, buzzer or indicator lamps to manually lap by point, and observe whether there are any Electrical, acoustic or optical signals to determine the continuity of each connection. Conducting the continuity test in this way is not only slow, inefficient, and labor-intensive, but it is also very prone to misdetection or missed detection.

After the wire harness is replaced, check whether the connection of the harness connector and the electrical equipment is correct and whether the positive and negative electrodes of the battery are connected correctly. During the power-on test, the battery's ground wire may not be connected temporarily. Use a 12V.20W light bulb as the test light. Connect the test light string to the negative pole of the battery and the pedestal of the frame and turn off all the electricity in the vehicle. equipment. The test light should not be on normally, otherwise it indicates that the circuit is faulty. When the circuit is normal, remove the bulb and use a 30A fuse to connect the negative pole of the battery to the ground of the frame. Without starting the engine, one by one, the power supply of each power device on the vehicle is switched on, and the electrical device and the line are checked. After confirming that the electrical device and the line are not faulty, the fuse is finally removed and the battery ground wire is connected.

The test and inspection of the automotive wiring harness can be done using a multimeter to measure the voltage and resistance, and a detection lamp and a special buzzer can also be used to check the short circuit. In order to ensure safety, dry batteries can be used as the power source for the 12V battery on the car before the inspection. Because the fuse is usually burned when a short-circuit fault occurs, the red lead of the multimeter is firstly connected to the load end of the open fuse, the black lead is connected to the ground part of the body, and then the finger is moved along the harness from the fuse holder. Tweak, shake, and shake the wire harness (the length of the wire is about 10 - 20cm for each move of the hand). When the hand touches the short circuit, the multimeter's reading should return to 0 (or close to o). If using detection lights and special buzzer

Check the short circuit, the detection light at this time, the buzzer beeps. In an overly dense and complicated wiring harness space, the above method may not be able to determine the specific location of the short circuit location. You can refer to the car wiring diagram, dismantle its accessories for inspection. The company then uses a short-circuit detector to perform inspections. At least, it helps to determine the short-circuit position of the wire harness. As soon as the division avoids dismantling the walls of all parts, it is easier to solve car breakdowns.

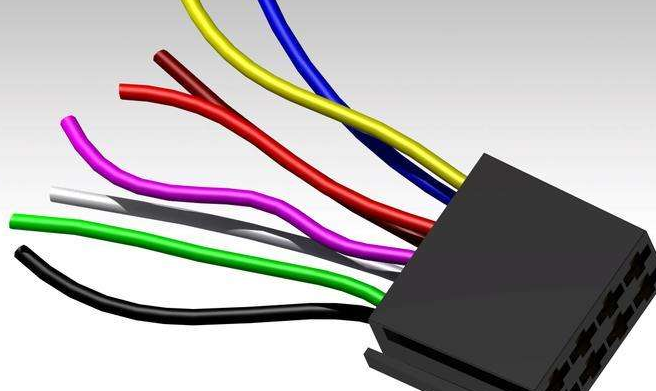

The inspection of the harness is an important means to ensure the quality of the harness. It usually runs through every link in the production. Since the wire harness mainly plays the role of connection, the crimping requirements for the terminal are very high. Table i shows the defined pull-off force of different cross-section wires.

RCCN WeChat QrCode

RCCN WeChat QrCode Mobile WebSite

Mobile WebSite