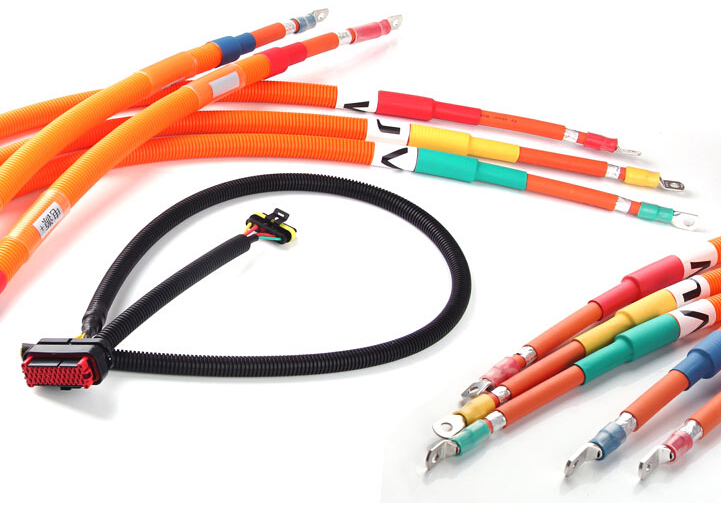

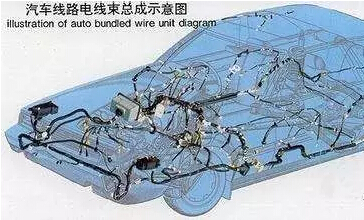

The car harness is the main body of the car circuit. At this stage, the form of the wire harness is generally composed of wires, connectors, harness wrapping materials and body fasteners. Automotive wiring harness to ensure that the transmission of electrical signals, but also to ensure the reliability of the circuit connected to the electrical and electronic components to supply the specified current value to prevent electromagnetic interference to the surrounding circuit, and to exclude electrical short circuit.

The design of the car harness fixed to the body is an important part of the layout of the wiring harness.

(A) wiring harness fixed in the body

Each harness generally with plastic cable ties, buckle hook, guard, etc. fixed in the body hole. Body holes are mostly round hole or oval hole, the general diameter of 5mm, 6mm, 7mm range.

1, the proposed two fixed point distance is not greater than 300mm;

2, the wiring harness around the need to add fixed point;

3, 120mm joints need to add fixed points to reduce the connector to withstand vibration and weight;

4, the branch of the branch points need to add fixed point;

5, the relative movement of the wiring harness, need to be fixed to each moving parts.

6, moving parts near the wiring harness fixed point and moving parts should be left> 50 mm gap;

7, need to maintain the location of the gap around the wiring harness, available hard pipe or splint;

8, to ensure that the direction of the wiring harness position can be used with the positioning of the buckle;

9, the wiring between the bundles of the jacket can be fixed with a jacket bracket on the body;

10, body length and thick, can be used to protect the body in the body to reduce the vibration and noise;

11, rice pieces are not allowed to open the hole, the weld cans, brackets or bolts fixed wiring harness.

(B) wiring harness through the door / car cabin vias

Car wiring harness through the general use of rubber parts for the transition to play a wear, waterproof, sealed and so on.

Mainly distributed in the following parts:

Engine and cab interface;

Front cabin and cab interface (left and right 2);

Four door (or back door) and the car interface;

Fuel tank imports and so on.

Commonly used materials are generally natural rubber, neoprene, silicone rubber, EPDM and so on.

Natural rubber characteristics: a good elasticity and mechanical strength, excellent resistance to flexing flexibility, a higher tear strength and good cold resistance. Disadvantages: anti-aging is not good, not oil and ozone, flammable.

Neoprene characteristics: resistance to ozone, heat aging, oil and other properties are better, with flame resistance and self-extinguishing; but low temperature resistance is not good.

Silicone rubber characteristics: heat resistance, cold resistance and weather resistance is better; the disadvantage is not oil.

EPDM characteristics: weather resistance, ozone resistance, heat resistance, corrosion resistance, acid and alkali performance are better, and have high strength and high scalability; Disadvantages: poor adhesion, and the elasticity of natural Good rubber, poor oil resistance.

In comparison, the overall performance of EPDM better, so now the automotive wiring harness with rubber parts generally use EPDM material.

(C) the electrical box of the fixed

In general, the car central electrical box is also counted as part of the car harness, used to place fuses, relays, steering flippers and key write relays starting relays, preheat relays and so on.

Central electrical box is divided into cabin electrical box and cab electrical box (some models only one)

Central electrical box is generally fixed with a guard, bolts, or with the electrical box itself designed to install the fixed structure directly on the body. The electrical box must be installed with sufficient margin to reserve space for the wiring harness and the removal of the fuse box. At the same time to ensure high temperature and humidity, temperature impact, wear, shock, corrosion and other requirements.

The reliability of the wire harness fixed to the vehicle directly affects the electrical performance reliability and harness life of the harness.

RCCN WeChat QrCode

RCCN WeChat QrCode Mobile WebSite

Mobile WebSite