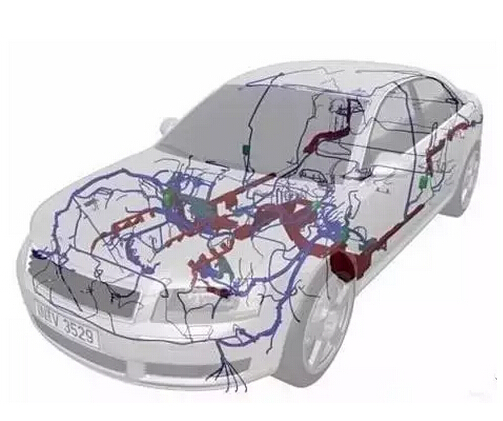

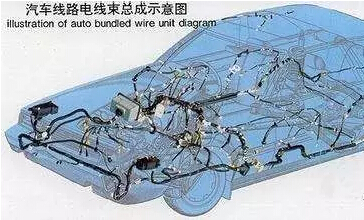

After the design of the automotive wiring harness system is complete, the reliability analysis and verification of the automotive wiring harness system is required. In order to ensure that the automotive wiring harness system has good reliability and safety, it is necessary to analyze the reliability of the design and raw materials.

1. Reliability analysis of the same road design

The electrical system of a car is composed of many circuits in the same way. It can be said that the design of the same channel is the core content of the electrical system. In normal automotive electrical system operation, the same path between different appliances is connected in parallel. If you want to check the reliability of the circuit, you need to connect the parallel channels together in series. In this way, the entire electrical system can only operate when all the wiring harnesses are on the same path. Therefore, it is generally used to check whether there is a problem in the co-channel design.

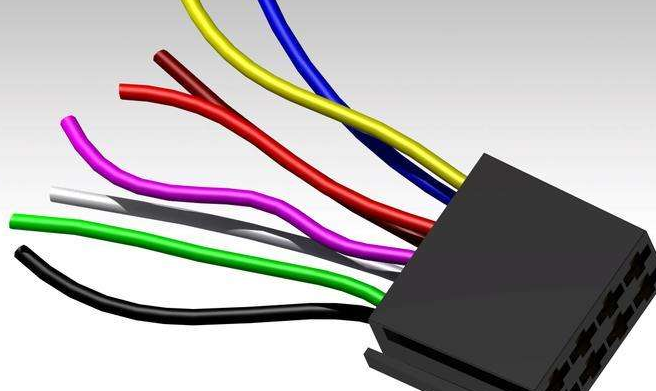

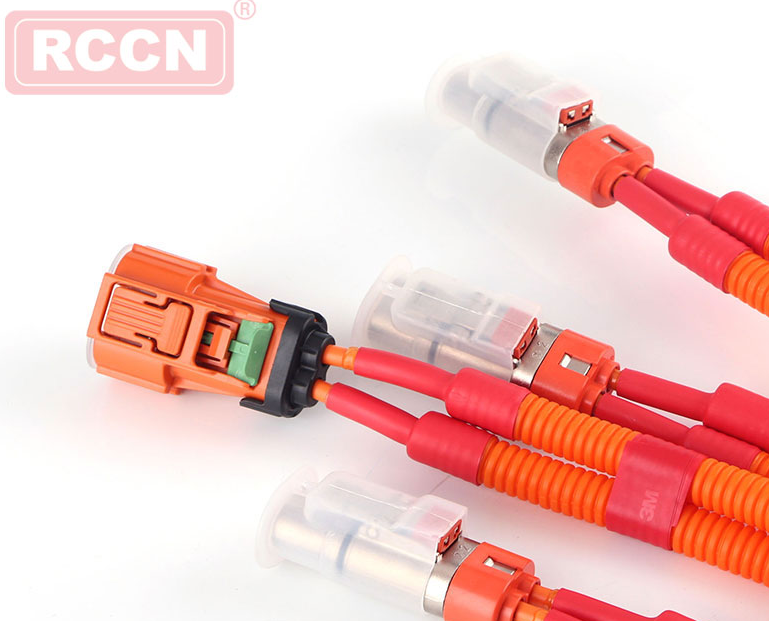

2. Reliability analysis of terminals and connectors

As an integral part of the automotive wiring harness system, the terminals and connectors are the main elements that determine the reliability of the wiring harness system and they play a vital role in the harness system. In many cases of problems occurring in the wire harness system, a large part is due to problems with the terminals and connectors, such as the aging of the terminals, and a series of problems such as falling, loosening, and damage due to a long time in the middle of the connector. Although these problems are a small detail in peacetime, it is due to their damage that leads to problems with the reliability of the final harness system.

3, reliability design of harness protection

As the overall performance of the harness design, it is necessary to comprehensively consider the reliable “winning design content” of the harness design, and from the overall perspective, propose a series of reliability measures. Including the selection of the design, the packaging materials are subjected to different comprehensive tests and experiments, and the integrated “winning and optimal” type is selected; when the online beam is designed, attention is paid to checking and testing at different stages to avoid unqualified The product flows into the next link and so on.

RCCN WeChat QrCode

RCCN WeChat QrCode Mobile WebSite

Mobile WebSite