Cable connector safety precautions

(1) Selecting conductors with appropriate conductivity and mechanical strength to receive;

(2) The inner diameter of the pressure receiving inner diameter and the outer diameter of the wire core to be connected are 0.8 to 1.4 mm;

(3) The resistance value of the joint after crimping should not be greater than 1.2 times that of the conductor of equal section, and the tensile strength of the copper conductor joint is not less than 60N/mm2;

(4) Before the crimping, the outer and outer surfaces of the conductor and the inner and outer surfaces of the conductor are coated with a conductive adhesive, and the oxide film is broken by a wire brush;

(5) The receiving, the sharp corners on the core conductor, the burrs, etc., are lubricated with a trowel or sandpaper.

2. Internal semiconductor shielding treatment.

Where the cable body has an inner shielding layer, it is necessary to reinforce the inner shielding layer of the receiving portion of the conductor when manufacturing the joint, and a part of the inner semiconductor shield of the cable is required to allow the inner shield of the connector to be connected to each other. The continuity of the inner semiconductor is ensured, so that the field strength at the joint receiving portion is evenly distributed.

3. Processing of external semiconductor shielding.

The outer semiconductor shield is a semi-conductive material that has a uniform electric field effect on the outside of the cable and cable joint insulation. It is the same as the inner semiconductor shield and plays an important role in the cable and the joint. It is necessary for the outer semiconductor port to be evenly arranged and also required to have a smooth transition with the insulation, and the semiconductor strip of the cable joint is connected to the external semiconductor shield of the cable.

4, the cable response cone processing.

During the construction, the shape and the correct and reliable counter-cone force cone are balanced on the whole cone surface. When manufacturing the cross-linked cable reflex cone, the special cutting tool is generally used, or it can be heated slightly with a slight fire. After cutting, after basic molding, scrape with 2mm thick glass, and then sand the paper from coarse to fine until the lubrication is reached.

5. Metal shielding and grounding treatment.

The effect of the metal shield in the cable and the joint is mainly used to transmit the short-circuit current of the cable, and the electromagnetic interference of the shielded electromagnetic field to the communication device. In the running state, the metal shield is at zero potential in the outstanding grounding state, after the cable is in trouble It has the ability to conduct short-circuit currents in a very short time. The grounding wire should be firmly welded. The metal shielding and armoring tape on the body of the two-headed cable should be firmly welded, and the grounding of the terminal should be firm.

6. Sealing and mechanical maintenance of the joint.

The sealing and mechanical maintenance of the joint is a guarantee for the safe and secure operation of the joint. The moisture and moisture in the cable joint should be avoided. In addition, the joint maintenance slot or the cement maintenance box should be installed in the joint orientation.

Related articles

-

BL-EM anti-electromagnetic metal cable connector IP68

BL-EM anti-electromagnetic metal cable connector IP68

-

Selection of connector plugs

Lighting industry is just a new industry, the system product quality is not a comprehensive understanding of the study is not deep enough, often appear quality and safety incidents, although the LED w

-

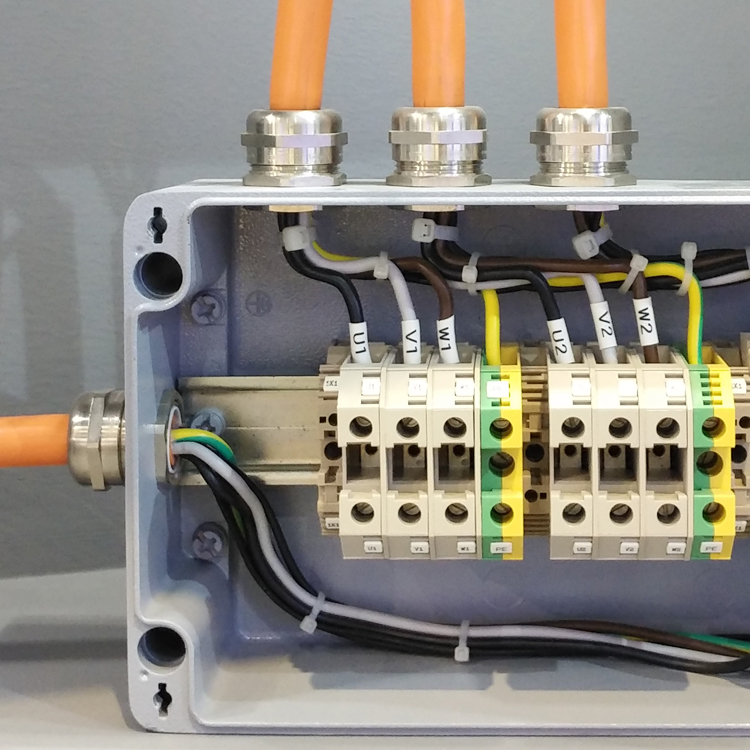

Metal cable connector in the motor installation effect diagram

Metal cable connector in the motor installation effect diagram

-

Metal cable connectors need to be properly installed and used

Cable connectors are the most common type of device at this stage. They are divided into different categories. We can see the most common metal joints, waterproof joints, etc. Although such a cable co

-

Metal cable connectors need to be properly installed and used

Cable connectors are the most common type of device at this stage. They are divided into different categories. We can see the most common metal joints, waterproof joints, etc. Although such a cable co

-

Cable joint material and performance

The cable connector is mainly used to connect the connector equipment between the two disconnected cables. The overall connection is good and has a certain tightness. Therefore, during use, leakage wi

-

Cable waterproof connector selection guide

As the name suggests, cable waterproof connectors can be applied to water-borne environments to provide a safe and reliable connector connector, the most important of which is the ability to achieve w

-

Cable joint fire protection method

The high-voltage cable joint fire protection method comprises the following steps: an explosion-proof temperature and humidity sensor detects the temperature and humidity in the fire protection box, a

RCCN WeChat QrCode

RCCN WeChat QrCode Mobile WebSite

Mobile WebSite