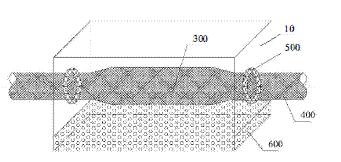

The high-voltage cable joint fire protection method comprises the following steps: an explosion-proof temperature and humidity sensor detects the temperature and humidity in the fire protection box, and the explosion-proof pressure sensor detects the air pressure in the fire protection box, and changes according to the temperature and humidity, the temperature difference per unit time and the temperature difference in the fire protection box. And the air pressure value generates a control signal; the first driving mechanism and the second driving mechanism respectively drive the first rotating louver and the second rotating louver to rotate from the first state to the second state according to the control signal, or rotate from the second state to the first state The first state is a closed state, and the second state is an open state. The invention can be applied to a humid environment, meets the heat dissipation requirements of the cable joint, and releases energy when the cable joint is exploded, and at the same time satisfies the fire and explosion of the electric power cable, and does not ignite the cable for other tunneling purposes. Requirements.

Specifically, it relates to a fire protection method for a high-voltage cable joint, which is suitable for fire protection of a high-voltage power cable dense place such as a cable tunnel, a cable trench, and a cable interlayer.

Cable fires occur mostly at cable joints. Cable intermediate joints are the weakest link in the safe operation of power systems. Cable breaks, short circuits, explosions and even serious accidents caused by overheating of cable joints are not uncommon. The cable connector of llOkV in a cable tunnel is set in the closed protection box. The inside of the protection box is filled with fireproof blocking material. The heat dissipation of the cable connector is unfavorable. When the joint explosion accident occurs, the energy is nowhere to be released, and the joint box bursts open, causing fire and burning phase. Adjacent to the cable, the city's power supply network is rampant.

Multi-regional power companies have put forward new fire protection requirements for power cables laid in power tunnels: One cable problem cannot be extended, and it cannot affect other cables laid in the same tunnel.

Cable tunnels and cable trenches in the underground are often unfavorable for ventilation and the environment is relatively humid. To prevent the cable connectors from getting wet, they are often protected by a sealed protective box. In some engineering applications, for power cables laid on different layers of cable tunnels, fireproof panels are installed in the place where the cable joints are connected, and the joints are separated from the upper and lower cable layers. However, the sealed protective box and the closed fireproof board are not conducive to heat dissipation of the cable joint, and are easy to generate heat accumulation, which is not conducive to the safe operation of the cable.

High-voltage cable joint fire protection method, can be applied to humid environment, meet the heat dissipation requirements of cable joints, and release energy when the cable joints explode, and at the same time meet the fire and explosion of one power cable, do not ignite to other tunnels The use of the cable is required.

RCCN WeChat QrCode

RCCN WeChat QrCode Mobile WebSite

Mobile WebSite