The rotor speed of a three-phase asynchronous motor is not synchronized with the rotating magnetic field, and does not exceed the speed of the rotating magnetic field. Because the induced current in the rotor coil of a three-phase asynchronous motor is due to the relative movement of the rotor conductor and the magnetic field. If the rotational speed of the rotor of the three-phase asynchronous motor is equal to the rotational speed of the rotating magnetic field, then there is no relative motion between the magnetic field and the rotor, and the conductor cannot cut the magnetic lines of force, so that no induced potential and current are generated in the rotor coil, The asynchronous motor rotor conductor is not subjected to electromagnetic force in the magnetic field to rotate the rotor. Therefore, the rotor rotational speed of the three-phase asynchronous motor cannot be the same as the rotating magnetic field, and is always smaller than the synchronous rotational speed of the rotating magnetic field. However, in special operating modes (such as power generation braking), the three-phase asynchronous motor rotor speed can be greater than the synchronous speed.

Since the rotating magnetic field of the three-phase asynchronous motor rotates in the same direction and at different rotational speeds, it is called a three-phase asynchronous motor instead of a three-phase synchronous motor.

The difference between a three-phase asynchronous motor and a three-phase synchronous motor is that the three-phase asynchronous motor has a slip ratio, while the three-phase synchronous motor does not.

The rotor of the synchronous motor is a fixed magnetic field, and the rotational speed is synchronized with the rotating magnetic field;

The rotor of a three-phase asynchronous motor is a squirrel-cage short-circuiting ring (or coil) that generates a rotational moment by a magnetic field line that cuts a rotating magnetic field.

The three-phase asynchronous motor rotates the stator magnetic field, causing the rotor to cut the magnetic field to generate a current. In order to reduce the current (imagine), the rotor rotates, but the speed is always slower than the stator magnetic field, so that it keeps rotating.

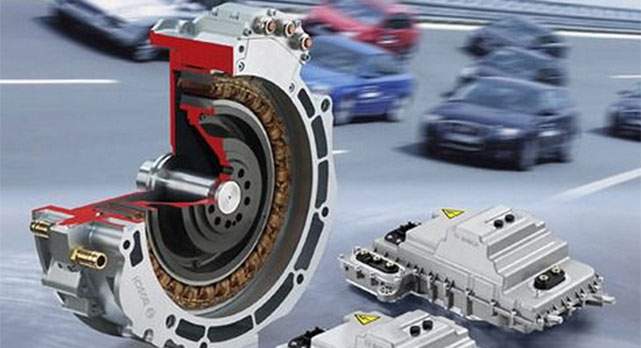

First of all, the three-phase asynchronous motor is only used for electric motors, and it is rarely used as a generator. It is a synchronous motor used to generate electricity.

The principle of the three-phase asynchronous motor is mainly to introduce three-phase alternating current into the stator to generate a rotating magnetic field, and the rotational speed is n0, that is, the synchronous rotational speed. Different pole pairs p, under the same frequency f=50Hz alternating current, will produce different n0, n0=60f/p.

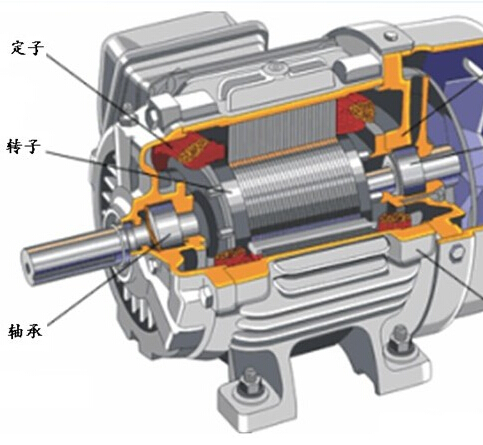

Three-phase asynchronous motor working principle

The symmetrical 3-phase winding is connected to a symmetrical 3-phase current to generate a rotating magnetic field, and the magnetic field line cuts the rotor winding. According to the principle of electromagnetic induction, e and i are generated in the rotor winding, and the rotor winding is subjected to electromagnetic force in the magnetic field, that is, electromagnetic torque is generated. The rotor is rotated, and the rotor outputs mechanical energy to drive the mechanical load to rotate.

RCCN WeChat QrCode

RCCN WeChat QrCode Mobile WebSite

Mobile WebSite

![[New energy] - electric motor principle](/upload/image/20170519/20170519090819_74516.jpg)