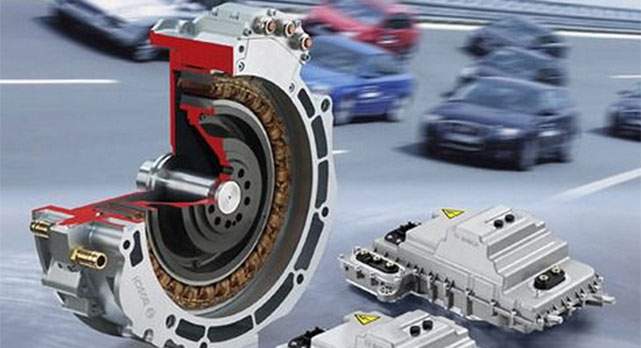

[New energy] - electric motor principle

1, what is the motor?

A: The motor is to convert the battery power into mechanical energy, driving the electric car wheel rotating parts.

2, what is the stator?

A: Brush or brushless motor does not rotate when working. Wheel-type brushless or brushless tooth motor motor shaft called stator, this motor can be called the stator motor.

3, what is the rotor?

A: Brush or brushless motor when working part of the rotation. Wheel type brushless or brushless toothless motor shell called rotor, this motor can be called outside the rotor motor.

4, what is the carbon brush?

A: brush inside the motor inside the top of the inverter surface, the motor rotation, the power through the inverter delivery to the coil, because its main component is carbon, called carbon brush, it is easy to wear. Should be regularly replaced and clean up the carbon.

5, what is the brush grip?

A: In the brush inside the motor to hold and keep the carbon brush position of the mechanical guide.

6, what is the commutator?

A: Brush inside the motor, with the insulation of the strip metal surface, with the motor rotor rotation, the strip of metal alternately touch the positive and negative brush to achieve the motor coil current direction of the positive and negative alternately to complete the brush motor coil Commutation.

7, what is the phase sequence?

A: The order of the brushless motor coils.

8, what is magnet?

A: Generally used to call the high magnetic field strength of the magnetic material, electric vehicle motors are used NdFeB rare earth magnet.

9, what is the brush motor?

A: When the motor is working, the coil and the commutator are rotated, the magnet and the carbon brush do not turn, and the alternation of the coil current direction is accomplished by turning the inverter with the motor and the brush. In the electric car industry brush motor high speed brush motor and low speed brush motor. Brush motor and brushless motor there are many differences, from the name can be seen brush motor has a carbon brush, brushless motor without carbon brush.

10, what is brushless motor?

A: The controller provides different current direction of the DC to reach the motor inside the coil current direction of the alternating changes, brushless motor rotor and stator between the brush and inverter.

11, how to achieve commutation motor?

A: brushless or brush motor in the rotation, the motor inside the coil power direction needs to change alternately, so as to achieve continuous rotation of the motor. Brush motor commutation * commutator and brush together to complete, brushless motor * controller to complete.

12, what is missing?

A: brushless motor or brushless controller in the three-phase circuit, there is a phase can not work. Phase loss phase and phase loss. The performance of the motor jitter can not work, or the rotation is weak and noisy. The controller is easy to burn in the absence of the state.

13, what kind of motor common types?

A: The common motor are: a brush with a hub motor, brushless gear motor, brushless gearless motor, brushless gear motor, side hanging motor.

14, from the type of motor on how to distinguish between high and low speed motor?

A: A brush with a hub motor, brushless gear motor is a high-speed motor;

B Brushless gear motor, brushless gearless motor is low speed motor.

15, how is the definition of motor efficiency?

A: The efficiency of the motor is the ratio of the electrical energy output by the motor to the power provided by the power supply. With the letter "ri" said.

16, brushless motor is how to classify?

A: from the phase angle can be divided into two categories, that is divided into 60 ° and 120 ° phase angle of the brushless motor; by speed points can be divided into high-speed brushless motor and low speed brushless motor; Position sensor to points, but also divided into a position sensor brushless motor and no position sensor brushless motor.

17, what is the positionless sensor brushless motor?

A: For the positionless sensor brushless motor must first be car pedal up, so that the motor has a certain rotation speed, the controller can recognize the brushless motor phase, then the controller can power the motor. Because it can not achieve zero speed start, so with very little. But because there is no sensor, all less a point of failure, and its lower cost.

18, brushless motor Hall power consumption is roughly the scope of how much?

A: brushless motor Hall power consumption range is roughly 6mA-20mA range.

19, brushless motor Hall voltage range is how much?

A: brushless motor Hall voltage range is generally in the 3-24V.

20, the general motor in the high temperature can work properly? How much can the motor withstand the maximum temperature?

A: If the measured motor cover temperature exceeds the ambient temperature of 25 degrees or more, indicating that the motor temperature has exceeded the normal range, the general motor temperature should be below 20 degrees. General motor coil is made of enameled wire wound, and enameled wire in the temperature above 150 degrees when the film will be because of the high temperature and fall off, resulting in short circuit coil. When the coil temperature of 150 degrees or more when the motor shell shows the temperature of about 100 degrees, so if the temperature of its shell is based on the motor to withstand the maximum temperature of 100 degrees.

21, the temperature rise of the motor should be below 20 ℃, that is, the temperature of the motor cover over the ambient temperature should be less than 20 ℃, but the motor heat more than 20 ℃ What is the reason?

A: The direct cause of motor heat is due to the large current caused. Generally may be short-circuit or open circuit, magnet demagnetization of the motor caused by low efficiency, the normal situation is the motor for a long time high current operation.

22, how to measure the phase angle of brushless motor?

A: turn on the controller power supply, the controller to the Hall element power supply, you can detect the brushless motor phase angle. As follows: with a multimeter +20 V DC voltage file, and the red pen then +5 V line, black table pen were measured three lead high and low voltage (here the use of red and black table pen has a skill), by 60 ° and 120 ° The commutation table of the motor can be compared.

23, if the 60 ° brushless controller with 120 ° brushless motor on what will happen? What about it?

A: will lead to the phenomenon of lack of phase, can not be normal operation; but Tianjin Song is developing an intelligent brushless controller can automatically identify the 60 ° motor or 120 ° motor, which can be compatible with two kinds of motor adaptation, making maintenance replacement More easily.

24, brush high-speed motor and brush low-speed motor What is the difference between intuitive?

A: A high-speed motor has a clutch (like the flywheel-like function), to a direction easily, to the other direction to turn effort; low-speed motor two-way turn are as easy.

B. High-speed motor car when the noise is large, low-speed motor rotation noise is small. Experienced people are easily identified by ear.

25, the motor starting current is how to define?

A: The general requirements of the motor starting current can not exceed its rated current of 2 to 5 times, which is why the controller on the current limiting protection is an important reason.

26, the market sales of motor speed why more and more and what impact?

A: A supplier speed can reduce the cost, the same low-speed motor, the speed of the coil less turns, but also save the silicon steel, the number of magnets is also less, the purchaser that the high speed like.

B. rated speed work, its efficiency unchanged, but in the low-speed area when the efficiency was significantly lower, that is, start weakness.

C. low efficiency, need to start with a large current, riding current is also large, the controller of the current limit requirements, the battery is not good.

27, how the motor abnormal heat how maintenance?

A: The maintenance method is generally to replace the motor, or maintenance.

28, the motor no-load current is greater than the reference table limit data that the motor failure, the reasons for what? How to repair?

A: The motor internal mechanical friction; coil local short circuit; magnet demagnetization; DC motor commutator carbon deposition. The method of repair is generally to replace the motor, or replace the carbon brush, clean up the carbon deposition.

29. What is the maximum fault-free maximum no-load current for all motors?

Motor rated voltage 24V when rated voltage 36V

Side hanging motor 2.2A 1.8A

High Speed Brush Motor 1.7A 1.0A

Low speed brush motor 1.0A 0.6A

High Speed Brushless Motor 1.7A 0.6A

Low speed brushless motor 1.0A 0.6A

1, the human race when the feeling of slow, strong sense of stagnation

(1) before the brake or brake (gate) and the rotating parts of the friction → adjust the front and rear brake and rotating parts of the gap, it is necessary to make flexible rotation, but also to ensure good braking brake performance.

(2) the chain is too tight → adjust the rear axle position before and after

(3) Front and rear axle and shaft components and cap tight or component wear → Loosen fasteners or replace wear parts.

(4) tires before and after the lack of inflatable tires inflated to foot.

2, the battery is sufficient but the load case two red light on the extinguished

(1) Charger output voltage is low → by charger repair method to troubleshoot.

(2) battery charging time is short → recharging to extend the charging time.

(3) battery pack or a single capacity drop → press the battery box repair method to troubleshoot.

(4) electrode damage or poor contact → replace the electrode.

3, in the driving in the stop, when the slow, weak and so feel

(1) seven-core connection bad → change seven-core line.

(2) Hall electric brake brake contact bad → change Hall brake brake.

4, the battery is full, full light, but the load wheel rotation powerless

(1) gear wear slip → replace the gear.

(2) Short circuit of the hub motor winding part → Replace the motor.

(3) Bicycle assembly problems or parts wear → Replacement damping rubber.

5, electric drive has irregular stop

(1) The controller and the motor hub connector are loose or poorly conductive → re-insert the connector or replace the plug-in.

(2) wheel motor charcoal brush and rotor contact bad → press the wheel repair method to troubleshoot.

6, power-driven noise

(1) wheel gear lack of oil → open the wheel, coated with gear grease.

(2) gear defect → replacement gear.

(3) gear housing bearing damage → replace the bearing.

Before removing the motor, first unplug the lead of the motor and the controller, and it is important to record the correspondence between the motor lead color and the controller lead color.

Open the motor cover should be cleaned before the site to prevent the debris was sucked in the motor on the magnet. Do the mark of the relative position of the end cap and the hub. Note: Be sure to loosen the screws to prevent deformation of the motor housing.

"17, what is the positionless sensor brushless motor?

A: For the positionless sensor brushless motor must first be car pedal up, so that the motor has a certain rotation speed, the controller can recognize the brushless motor phase, then the controller can power the motor. Because it can not achieve zero speed start, so with very little. But because there is no sensor, all less a point of failure, and its lower cost. "

Related articles

-

One minute a comprehensive understanding of new energy vehicles motor

Now the development of electric vehicles faster and faster, and electric vehicle motor research and development, but also aroused our concern, but really understand the electric car motor is very few people. Xiao Bian for everyone collecting information, as we have a good talk about electric car motor knowledge. Let us explore the next high-tech car heart!

-

Introduction to Electric Motors

Refers to the law of electromagnetic induction in accordance with the conversion or transmission of electrical energy of an electromagnetic device. Motor (also known as motor), in the circuit with the letter "M" (old standard with "D") said. Its main role is to generate drive torque, as a power source for electric vehicles.

-

And now move from the beginning of the five ministries how to adjust the new direction of new energy vehicles

Xiong Guan Man Road, such as iron. And now move from scratch. 2016 annual sales of both breakthrough 500,000, the new energy automotive industry how to continue the sound and fast development? The ind

-

new energy

New energy (NE): also known as unconventional energy. Refers to the traditional energy sources outside the various forms of energy. Refers to the beginning to develop or use or are actively studying, to be the promotion of energy, such as solar energy, geothermal energy, wind energy, ocean energy, biomass and nuclear fusion energy.

-

New energy auto market gradually restored power battery polarization

A paper plan, to the downturn of the new energy auto market hit a shot in the arm.April 25, the Ministry of Industry, Development and Reform Commission, Ministry of Science and Technology issued the"l

-

A variety of motor principles to understand the more profound

Through the intuitive motor animation, to understand the working principle of the motor!A motor (commonly known as"motor") refers to an electromagnetic device that converts or transmits electricity ac

-

New energy automotive industry - Nissan supply product line

http://cn.rccn.com.cn/products_NewProduct_27.html New series of Richenghttp://cn.rccn.com.cn/products_PCBParts_24.html Richeng isolation column series&n

-

PV people need to pay attention to Trump in the new energy field layout

Putin as the helm of Russia, not only in the political, diplomatic and economic aspects of the extraordinary performance, the same in the future development and norms of new energy also has a forward-

RCCN WeChat QrCode

RCCN WeChat QrCode Mobile WebSite

Mobile WebSite