Three-phase asynchronous motor structure is simple, reliable, easy maintenance.

Three-phase asynchronous motor structure is simple, reliable, easy maintenance.

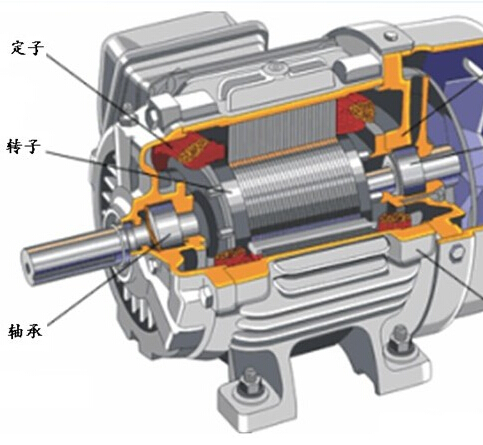

Motor small series tells you three-phase asynchronous motor is mainly composed of two parts of the stator and rotor, including chassis and end caps, etc., if it is closed motor, there are cooling fans and protective fan end cover.

The stator includes the base (housing), the stator core and the winding.

Small and medium-sized three-phase asynchronous motor chassis and end caps made of cast iron, if it is a closed motor, the shell surface with a heat sink, used to dissipate the internal work of the heat generated by the motor.

Stator, rotor core is generally made of 0.5mm thick silicon steel sheet with a piece of out of the mold, and then made of laminated.

The role of the core is magnetic, stator core inner circle is used to insert the stator winding, the rotor outer edge of the groove is inlaid with cast or cast aluminum.

Stator winding is the key component of the electromagnetic energy conversion of the motor. It is made of various kinds of copper made of insulating wire and is embedded in the stator slot.

Three-phase asynchronous motor a total of three-phase winding, according to the design requirements can be made several different speed or different power.

The rotor consists of a rotor core, a rotor winding, a rotating shaft and a bearing.

Rotor core is formed by the core punching, and also part of the motor magnetic circuit, the rotor winding has two basic forms: winding and squirrel cage type.

Small and medium-sized three-phase asynchronous motor rotor windings are in this form, the winding is made of copper wire or aluminum rod and end ring composition.

The guide bar can be a copper strip per slot, welded at both ends of the copper ring to form a rotor winding. In order to save copper and improve production efficiency, small and medium-sized asynchronous motor rotor winding used aluminum, with molten aluminum liquid guide, end ring and ventilation and cooling of the fan once cast.

Compared with the winding type, cage rotor structure is simple, easy to manufacture, work reliability, the shortcomings of the starting torque is small.

RCCN WeChat QrCode

RCCN WeChat QrCode Mobile WebSite

Mobile WebSite

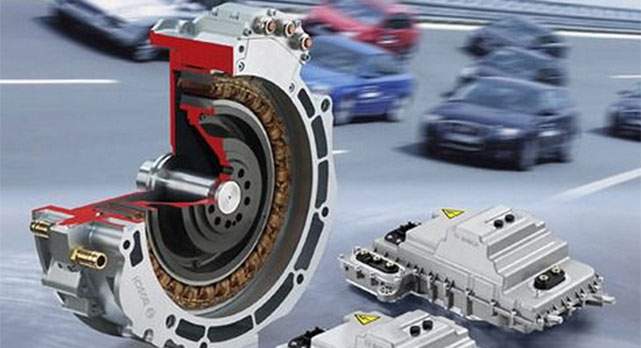

![[New energy] - electric motor principle](/upload/image/20170519/20170519090819_74516.jpg)