In order to ensure the quality and reliability of the harness, the research and development of the automobile harness detection system is of particular significance. At present, the domestic automotive field of self-developed harness detection system is also based in the blank. Based on the analysis of the actual situation of harness detection problem, a theory and method of harness detection is proposed, and a computer harness detection system is designed by combining microcomputer and single chip microcomputer.

Solving the Key Point Model of Harness Path

The "path" layer is the expression and record of the "time" dimension of the moving harness movement process. The entire motion process includes multiple moments, so the & quot; path & quot; corresponds to a list of & quot; path key & quot; information from a number of different times that will record the active harness at all times throughout the motion Pose information, the path key information stored in chronological order, the formation of "path key" list. The form of storage can be a matrix. At this point the storage is on the "path" level. Obtaining the path key information from the "path key" list in the "path" and substituting the information into the established physical characteristic model to obtain the location information of all the nodes corresponding to the path key, The spatial posture of the entire active harness corresponding to the path key.

The results of the domestic correlation mainly focus on the static layout design and assembly simulation technology of the wiring harness, and less access to the literature on the modeling of the characteristics of the wiring harness. The flexible variable characteristic of the wire harness is proposed by the North East Polytechnic University, The variable length discrete control point modeling method of the harness under the environment and the interactive wiring method based on the discrete control point model.

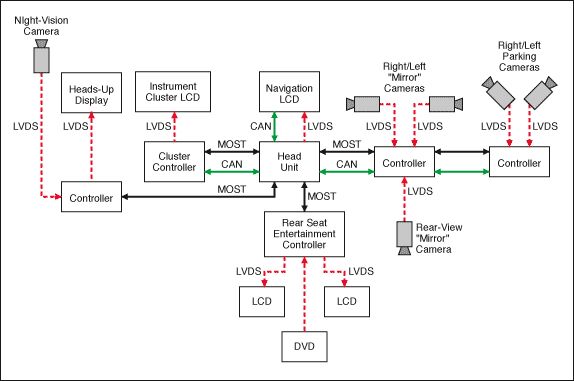

Car Harness Node Connection Scheme

Modulus hybrid system uses a harness impedance of 75 ohms, which is determined by the physical properties of the automotive wiring harness, the media process is poor (such as wire harness inside the conductor of the foam is not the right or foam uneven), due to the beam Impedance and Equipment Impedance Mismatch Initiation Harness Notch. Therefore, before using the new wiring harness, use the sweeter to observe the amplitude and frequency characteristics of the harness to see if there is no trap point. To this end, the design of an electrical system bearing platform, taking into account the load platform static structure and dynamic response problems, according to the fixture on the load platform to install the location of the design of four different structures, and in the initial stage to establish this Several structural 3D models. The groove in the figure is the fixed mounting position of the follower fixture, and the small plate connects the bearing platform and the vibration table to be excited together. The finite element model is modeled by the solid element, and the mass reduction is compensated by the mass compensation before the finite element model is submitted to calculate the mass reduction due to filling the holes to ensure that the mold The accuracy of the state analysis results.

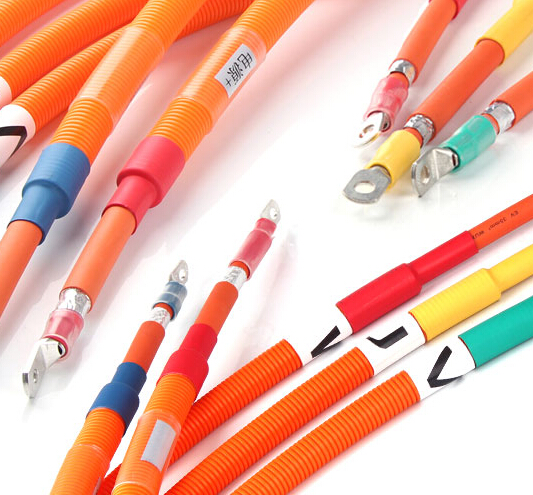

After the harness assembly of the harness is determined, the assembly path planning can be performed for each harness branch. In addition, the wiring harness and electrical components in the assembly process, the system will automatically go to the database to find the harness connection port information to match, check, if there is a contradiction, then issued a warning to avoid wiring harness misplaced. As the car wiring harness more, in the process of integrated wiring process, in accordance with the wiring process requirements for sub-line, line, banding and fixed operation, integrated wiring is completed, the connector is relatively fixed, harness space activity margin is small, The detection of more difficult, first of all too many people involved in the reliability of the whole there is a certain impact, followed by a large number of detection tasks can not guarantee the product development cycle, so the introduction of special automatic detection equipment for detection is imperative.

RCCN WeChat QrCode

RCCN WeChat QrCode Mobile WebSite

Mobile WebSite