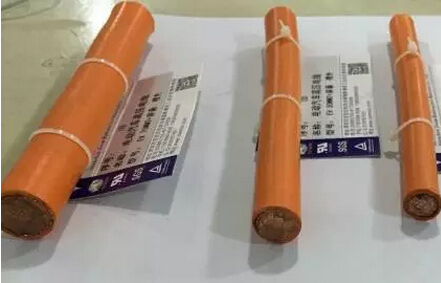

The growing problem of environmental pollution has made the government spare no effort in promoting the development of environmental protection industry, especially the promotion of electric vehicle industry. The resulting demand for electric vehicle system harness matching is significantly increased, but most of the traditional automotive wiring harness business can not provide in line with the technical requirements of electric vehicle wiring harness cable products.

How to shield the electric vehicle when the high-voltage operation of the electromagnetic interference caused by the problem, as well as the harness and connector sealing performance problems, hybrid electric vehicles required by the high pressure, high temperature, gasoline / diesel / cooling water, Problem, automotive space design on the softness of the wire and strength, etc. have put forward higher requirements. In the design and development of hybrid and pure electric vehicles, these issues need to be considered and resolved, otherwise it will produce security risks.

Electromagnetic wave shielding, wiring harness interference solution.

Electromagnetic wave shielding, wiring harness interference solution.The hybrid has attracted much attention due to its fuel economy, but it also poses a problem for automakers, which is electromagnetic interference (EMI). It is always necessary to optimize the electromagnetic interference with electronic modules and harness designs, even in 12V systems. This harmful noise can interfere with radio reception and other vehicle signals such as AM / FM radio frequency, mobile phone use and Bluetooth performance. Hybrid electric vehicles must rely on high current high voltage inverter to drive. But the high-power inverter will produce electromagnetic interference in the frequency range of 100.0kHz to 200.0MHz. The high-power AC and DC conversion of these inverters makes the electromagnetic interference problem of hybrid vehicles more serious.

In contrast, when the AC is converted to direct current, the battery pack is charged, the weight of the electronic device is lighter, and thus the performance of the transformer is superior to that of the transformer. In fact, the electronic device is currently the only viable technology for AC and DC conversion, driving the vehicle with a battery pack. However, these electronic devices will produce more electromagnetic interference, because the high voltage wiring harness will act as an electromagnetic interference antenna, the electromagnetic interference to the entire body.

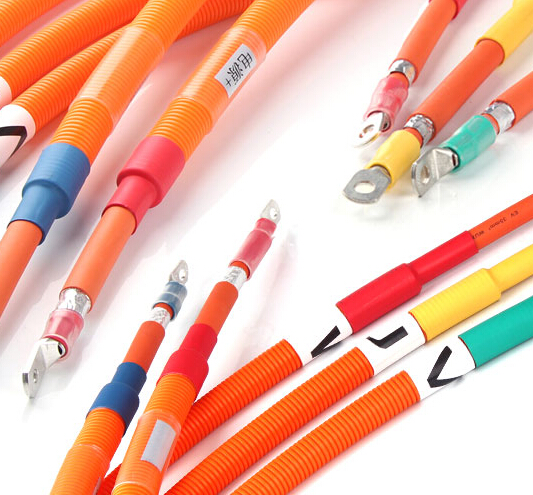

Conventional vehicles, the most effective way to suppress electromagnetic interference noise is often the use of capacitors, sensors, diodes and other components. But now, shielding electronic modules and shielded wire harnesses become a more economical solution for electric vehicles because it is smaller and lighter than traditional suppressors.

Harness connector for the use of security problems.

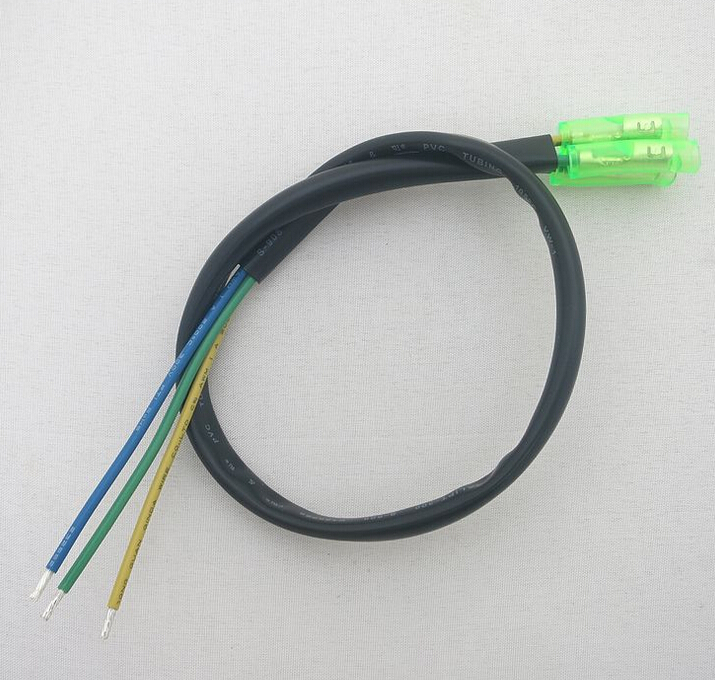

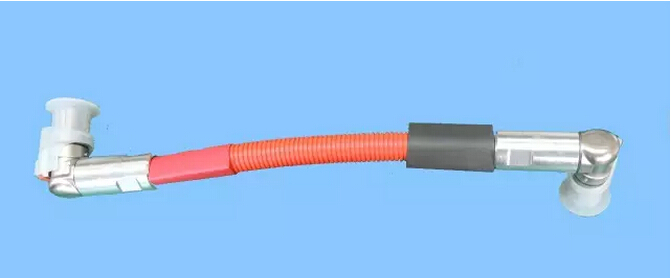

To ensure the safety of drivers and service technicians in high-pressure environments, we must consider a number of complex factors in the electrical system to ensure reliability and optimality. The connection system is a key component of a high voltage electrical wiring harness, especially a high power line harness design. From the safety point of view, high voltage connection system design should pay attention to two aspects, namely high voltage interlock circuit (HVIL) and the connector of the environmental seal (in the vehicle to avoid short-circuit between the high-voltage terminals).

As the line is not sealed may lead to such as short circuit and other failure mode, and thus high-voltage circuit seal is essential. As we all know, water and electricity are incompatible. Use a wire loop seal and a connector seal to allow the connector to be truly sealed to ensure that moisture can not enter without causing overheating or sparks. Compared to the traditional 12V system, high voltage systems require a more robust seal, because the higher the voltage, the greater the chance of flashover.

Key words: electric vehicle harness high voltage harness harness production

RCCN WeChat QrCode

RCCN WeChat QrCode Mobile WebSite

Mobile WebSite