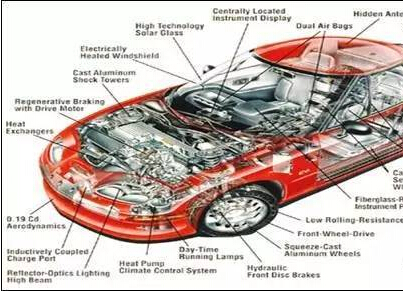

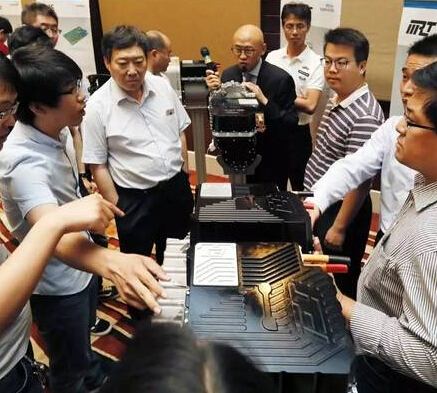

The automobile wiring harness is the network main body of the automobile circuit and is the carrier of the automobile circuit. Automobile wiring harnesses are the bridges and ties for the operation of vehicle electrical components, and are the nervous system for the distribution of power and signal transmission of vehicles. The electric vehicle high-voltage harness can be connected to the internal and external wiring harness of the electric vehicle according to different voltage levels. Mainly used to distribute the internal wiring harness signal of the power distribution box, transmit power efficiently and with high quality, and shield external signal interference. The high voltage connection system consists of a high voltage harness and a connector. DC/DC, plumbing PTC charger, wind heating PTC, DC charging port, power motor, high voltage wiring harness, maintenance switch, inverter, power battery, high voltage box, electric air conditioner, AC charging port, etc. all need to use the connector; High-voltage harnesses are the neural network of high-voltage systems for new energy vehicles and are very important. Whether the high-voltage harness can continue to work safely and efficiently, the protection of the harness insulation is particularly important. A good harness sleeve can effectively protect the high-voltage harness of the car from normal operation. What are the technical specifications for high voltage harness casing?

First, the color of the harness protection sleeve

The protective cover of the wire harness includes a wire bundle bellows and a heat shrinkable sleeve.

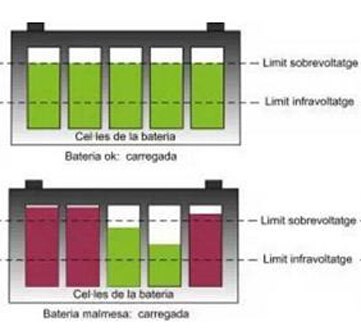

The color of the bellows is orange (GB30) or orange bellows.

The color of the heat shrinkable sleeve: the polarity is differentiated by different color heat shrinkable sleeves, the positive pole is red, the negative pole is blue, the U phase is yellow, the V phase is green, and the W phase is red.

Second, the length of the harness

1 cable length

According to the overall layout of the vehicle and the wire harness layout diagram, the required length of the cable is measured. Based on the measured length, it is advisable to increase the margin not exceeding 200 mm.

2 wire bundle bellows length

Depending on the length of the cable, the length of the cable into the component must be subtracted from the length of the cable. The specific value of the subtracted length depends on the specific component.

3 heat shrinkable sleeve length

At both ends of the bellows, the heat shrinkable sleeve must be hot to ensure that the bellows and the cable are not shaken. The length of the heat shrink tubing shall be equal to the length of the cable into the component.

RCCN WeChat QrCode

RCCN WeChat QrCode Mobile WebSite

Mobile WebSite