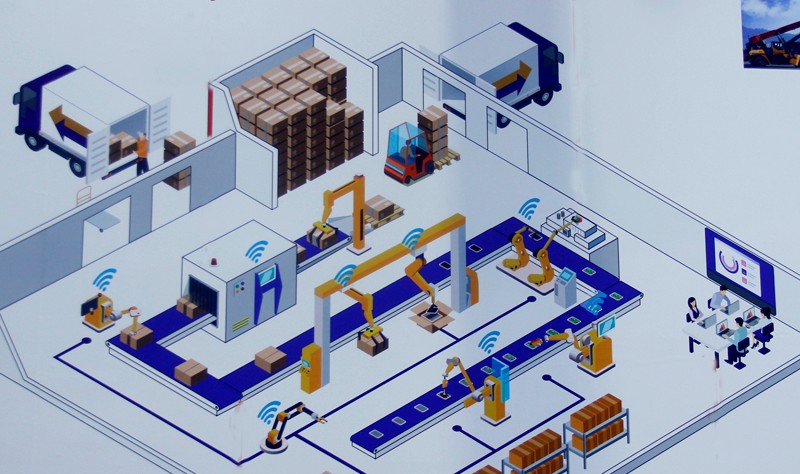

Smart manufacturing has become an important trend in global manufacturing. As the demographic dividend disappears, factories need to find a new production model to alleviate the cost of labor and respond to rapidly updated product demands. The emergence of the Industry 4.0 model has provided new ideas for the manufacturing industry. Through the IoT to connect all phases of the product lifecycle, from raw material procurement to production to delivery and into the customer's home, the entire process can be visually managed.

This is also the scene of the fourth industrial revolution. The Internet of Things has built a bridge for the entire manufacturing process and created a cohesive manufacturing environment. The material supplier knows when it should be shipped, the manufacturer knows how to ensure the quality of the product, and the feedback from each customer gives the manufacturer a new understanding of the product and the market. The Internet of Things solves the information gap between the supplier, the manufacturer and the customer. The problem is that smart factories take manufacturing service capabilities to a whole new level.

In the future, the Internet of Things will bring tremendous value to the manufacturing industry, and the potential value may reach several hundred trillion US dollars. It is estimated that at a rate of 6% per year over the next five years, the market will approach $70 billion by 2020. Huge application scenarios include automotive and transportation, mining, electronics, chemicals, pharmaceuticals, oil and gas. So, how will the new manufacturing scene change and how will the factory companies meet the trend?

Manufacturing supply chain transformation

The demand for the consumer market is changing so fast that it is a big problem for traditional manufacturing. Customers' real-time expectations are rising, supply chains are becoming more and more complex, and it is difficult to meet current market demands through manual analysis or backward tools to manage and control the manufacturing process. Smart factories use a large amount of real-time data collected by smart sensors and the Internet of Things, and then based on the analysis of high-power servers in the cloud, and create more flexible production processes to keep up with customer demand.

The smart manufacturing model is completely different from traditional manufacturing. Based on advanced digital manufacturing technology, the factory can produce on-demand, source raw materials from suppliers around the world, avoid the risk of large inventory, and manage customer feedback through social media to achieve individuality. Manufacturing to achieve faster, more flexible, and more efficient product delivery levels.

Thanks to the development of the Internet of Things and digital technology, smart manufacturing has brought new capabilities to the factory. Although upgrading smart factories is not necessary, it is very valuable. The use of an optimized supply chain not only reduces lead times and costs, but also reduces the number of defective products in the production process based on market information.

Product quality remains consistent

In the past manufacturing industry, when the factory received the workshop information or the customer survey to the data, the product has entered the customer group, that is, the damage has already occurred, leaving the user with a low quality impression. The new manufacturing model, with the help of IoT technology, allows factory companies to collect and transmit data in real time, providing timely insight into the problem and making changes before the product causes serious problems.

Future products will be equipped with smart sensors that will ensure the quality level of each product. Whether it is consumer electronics, household appliances or industrial equipment, the sensor can report abnormal data of the product to the manufacturer, and then the factory provides more Punctual after-sales service. In addition, the factory can analyze the deficiencies of the products from the data and optimize them on the next product, which will ultimately ensure the quality of the products.

This approach avoids customer complaints and damage to the company's brand, and can cost the company significant costs. In the past, after major problems with automobile products, a large number of recalls were not uncommon, which not only led to a decline in the influence of the company's brand, but also a heavy financial cost.

The benefit of the IoT connection manufacturing process is that once a problem or defect is discovered, it can be self-healing in time before the error has serious consequences. Especially in today's breakthrough of artificial intelligence, we can quickly analyze the hidden dangers, complete the control of production quality in near real time, and bring better products and less losses.

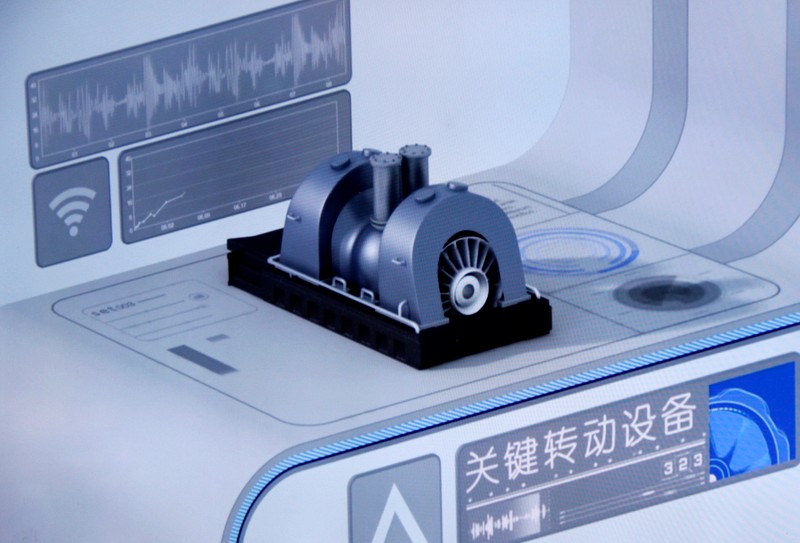

The important value of predictive maintenance

Unplanned downtime of the factory production line and unplanned maintenance will bring huge losses to the enterprise. It is impossible for every piece of equipment and machinery to remain unproblematic, but the downtime occurs outside the plan, which not only causes the company to suffer production losses. At the same time, it also drags down production efficiency. Today, when the cost is getting more and more expensive, such unplanned downtime may take a long time to check the repairs, and it will cost a lot of money, which is unbearable for SMEs.

In the Industry 4.0 model, there is a predictive maintenance method that automatically monitors machine wear in real time by placing various sensors on production equipment in a smart factory. By using machine learning algorithms, you can accurately track part and machine replacement times.

Predictive maintenance helps to arrange replacement parts of the equipment before the error occurs, and can arrange for a reasonable replacement time, such as when the machine is idle, without taking up production time. This not only ensures the efficiency of the production line, but also improves the overall agility of the plant.

How to build a smart factory?

Smart factories are an inevitable trend in the future development of the manufacturing industry. There are already some excellent cases, such as the world's major manufacturers including General Electric, Siemens, Honeywell, Mitsubishi Electric, Rockwell Automation, Schneider Electric, General Dynamics, etc. Are trying new manufacturing models. However, to upgrade smart factories to meet their own needs and environmental characteristics, different companies should adopt different methods in order to achieve the desired results.

Usually, enterprise transformation has several goals, such as slowing down labor costs, reducing the overall cost of the plant; increasing the efficiency of the production line, shortening the delivery time of the product; increasing the flexibility of the factory so that it can respond quickly to market demands and so on. Enterprises can create complete upgrade plans according to their own needs.

First of all, we must build the Internet of Things to connect sensors, motors, switches and other small tools. The smart factory in the industrial 4.0 era includes production lines, robots, the Internet of Things, and remote automation. In addition, it involves production networks and custom production systems, virtual planning of products, and production and remote maintenance.

In addition, smart factories need new workers and introduce professionals with IT knowledge and OT operation technology. Repetitive labor tasks in the factory will be handed over to the robot, and people will pay more attention to product design, process optimization and monitoring.

RCCN WeChat QrCode

RCCN WeChat QrCode Mobile WebSite

Mobile WebSite