R&D background:

The laying of communication cables is an indispensable task in communication engineering. The traditional communication cable laying process is to first excavate the trenches and then build the wells in the trenches to form the tube wells. It is labor intensive, time consuming and efficient. Low, it is not conducive to the late replacement, maintenance and overhaul of the cable. Some existing pipe wells are used for laying and directly filling the pipe wells into the trenches. However, such pipe wells are usually directly filled with cement into a well type structure, the structure is relatively simple, and the cable opening on the tank body is rough. Dragging the cable during the laying of the cable is likely to damage the surface of the cable, and the operation is also time consuming and laborious, which is not conducive to the smooth development of the construction project.

solution:

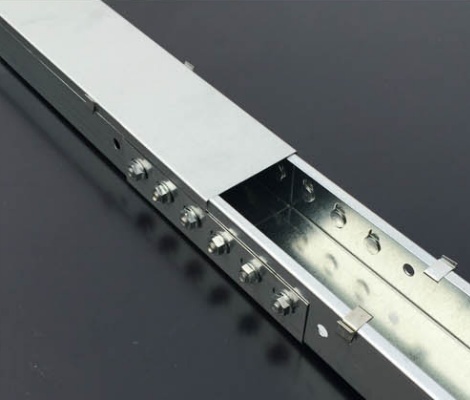

The communication cable trough includes a trough body, the trough body is formed by splicing a prefabricated bottom plate and a side plate, the upper end of the trough body is connected with a well seat, and the upper part of the well block is provided with a cover plate for assembling a recessed platform, wherein the bottom plate is provided with a card slot for fixing the side plate, each side plate is inserted into the card slot and the adjacent side plates are fixedly connected by a corner piece, and the side plate is provided with a cable opening. A cable protection kit is disposed in the cable opening, the cable protection kit includes an outer tube, an inner tube and an elastic connecting rib, and the inner tube and the outer tube are connected by at least two connecting ribs, the inner tube and the outer tube Each of the tanks is provided with a bracket near the cable opening, and the bracket is provided with a roller assembly perpendicular to the axial direction of the communication cable, and the roller assembly includes a first roller disposed horizontally And a second roller and a third roller disposed on both sides of the first roller, the bracket is a U-shaped frame, and the frame is provided with a bearing seat for connecting the roller assembly, the first roller The wheel, the second roller and the third roller are arranged in a U shape.

Product advantages:

The cable trough is installed in the cable opening of the trough by the cable protection kit. When the communication cable passes through the cable opening, the cable protection kit can prevent the cable from contacting the inner wall of the cable opening and prevent the cable surface from being scratched. It has a good protection and guiding function. At the same time, the communication cable can be assisted by the roller assembly. When the communication cable is bent and laid in the tank, the frictional resistance can be reduced, the operation saves time and labor, the work difficulty is reduced, and the construction quality is guaranteed. Improve construction efficiency.

RCCN WeChat QrCode

RCCN WeChat QrCode Mobile WebSite

Mobile WebSite