With the development of the automobile industry, the advancement of science and technology, the emergence of new light sources and the aesthetics of people, automotive lighting has been continuously improved, the structure is more and more complex, the process is more and more sophisticated, and the functions are more and more perfect. Modern car lamps have become a beautiful craft with high-tech connotations, and are a pair of beautiful "big eyes" of cars. The evolution of automotive luminaires has gone through four stages, and the emergence of the fourth generation of LED automotive light sources has had a profound impact on the transformation of automotive luminaires.

Enter the third and fourth generation light source period

There are cars in the world that have lights. Automotive lighting can be divided into two categories: lighting devices and indicating signal devices. The function of the lighting device is to illuminate the road ahead of the car in the dark. There are headlights, front fog lights, reverse lights and license plate lights, which can include interior lights, instrument lights and luggage lights. The function of the signal device is to indicate to other road users the presence and driving state of the vehicle, such as turn signal lights, brake lights, position lights and rear fog lights. There are lights and specifications and standards for the lights, which are stipulated for the light source, light color, light intensity, light shape and installation position of the lights.

The heart of automotive luminaires is the light source, and the evolution of automotive luminaires occurs with the change of automotive light sources, generally through the following four stages:

The first generation of car light source is directly burned by fuel (candle, kerosene or acetylene), which can meet the requirements of early car lights, but has obvious shortcomings such as low luminous efficiency, weak light intensity, unstable performance and complicated operation.

LED light sources have the following characteristics:

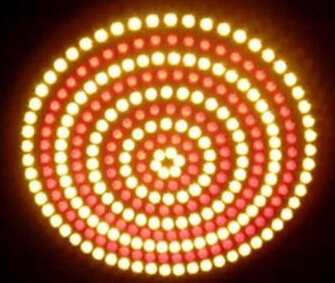

First, the monochromaticity is good and the colors are rich and colorful. The color saturation reaches 130% full color, making the light clearer and softer. Second, long life and good earthquake resistance. LEDs are semiconductor components. Unlike incandescent lamps, there are no fragile movable parts such as glass and tungsten wires. The fault is extremely low and maintenance-free. Third, the response time is short, only 60 nanoseconds, especially suitable for the light source of automotive lamps, for the driver to fight for valuable time to reduce accidents. Fourth, high efficiency, low energy consumption. The LED light source can directly produce the red, amber and other colors required by the automobile lamp without filtering color, and has no loss, and the power utilization rate is as high as 80% or more. 5. Small size and light weight. With its characteristics, it can design thin, light and compact lamps of various styles to provide space for automotive design. Sixth, green lighting source. The LED spectrum has good monochromaticity, no extra infrared, ultraviolet and other spectra, no mercury harmful substances, and little heat and radiation. 7. The luminous flux of a single LED is small. At present, the research level of luminous flux of a single LED can reach 120lm/W, the product level is ≤60lm/W, and the high-power LED often needs to increase the size of the heat sink, so the LED light source generally adopts the LED array design method. Eight, plane lighting, strong directionality. It is different from the point source incandescent lamp, the viewing angle is ≤180°, and the design must pay attention to and use the LED light source to have different viewing angles and not more than 180°. Nine, the luminous efficiency of LEDs decreases with increasing temperature, and the general chip temperature will exceed 120 °C. Thermal design must be considered in the design of the luminaire assembly design and manufacturing process. X. LEDs are multi-component compound semiconductor components. The characteristics of multi-component semiconductor devices are that their electrical, optical, thermal, and mechanical parameters are highly discrete. In design, we must fully consider this feature, and require component production companies to strictly classify and classify components according to the requirements of LED light sources for automobiles.

RCCN WeChat QrCode

RCCN WeChat QrCode Mobile WebSite

Mobile WebSite