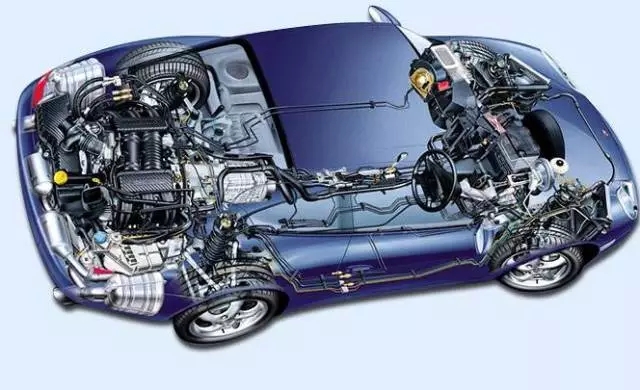

How to ensure the quality assurance of automobile wiring harnesses during processing, let us discuss the following points together.

1: Every link must be controlled. After the product is formed, it must be checked for its wire diameter and appearance, so as to effectively ensure the quality of its line;

2: Directly through the inspection of its line to achieve the control of its quality, so that it can be used for efficient production, the quality control standards must be done well, so that the current situation can be effectively analyzed

3: The work of each link is very good to control the quality of its production from the source, which can effectively reduce the failure rate of its products and do a real high efficiency and high quality production.

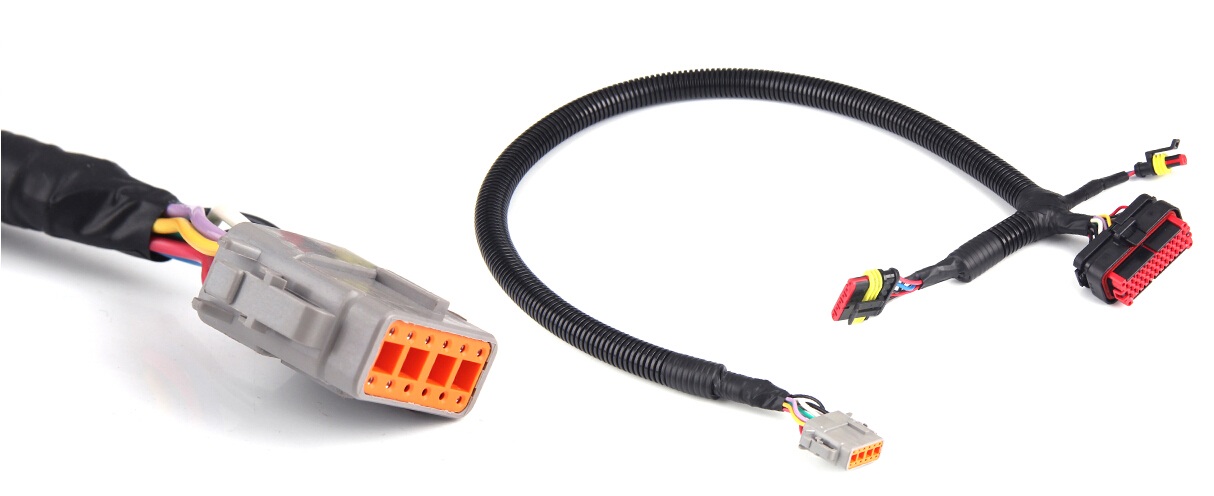

4: The length of the wire harness processing also includes the total length of the entire wire harness, the length of each branch in the product and the length of the flying space between the wire ends. In the process of processing, the product actually has a plurality of wire harnesses, mainly branching wires and Main harness.

RCCN WeChat QrCode

RCCN WeChat QrCode Mobile WebSite

Mobile WebSite