1. Power battery manufacturing and processes are complex and difficult to dismantle

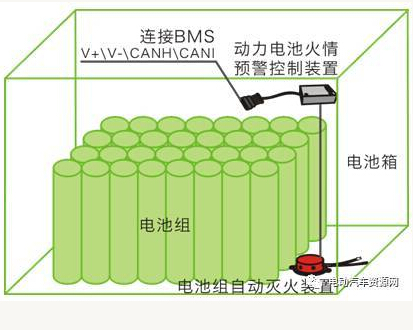

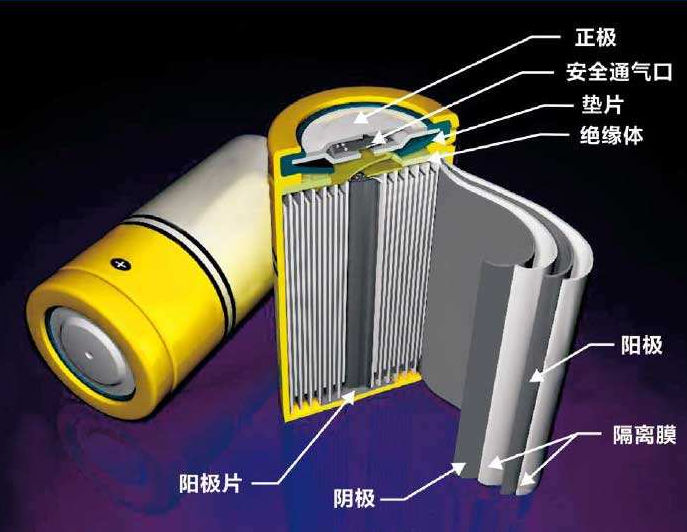

Power battery recycling, first to do a step is to dismantle it, but there are a variety of different power batteries on the market. In the forthcoming implementation of the new standard for electric vehicle terminology, batteries are divided into three types according to the package type, including cylindrical batteries, square batteries, and soft-pack batteries. If the battery materials are divided, more. Each type of power battery has its complex manufacturing technology and process design, so the dismantling process cannot be automated. This means that, in the case of a low level of automation, the dismantling process needs to be completed manually, and the technical level of each worker is not uniform, and the non-uniform technical level encounters a different type of battery. The difficulty can be said to be very high. Any mistakes in the dismantling process may result in pollution or safety problems, both of which are very dangerous.

2. The quality of the recycled battery is not uniform and the processing technology is lacking

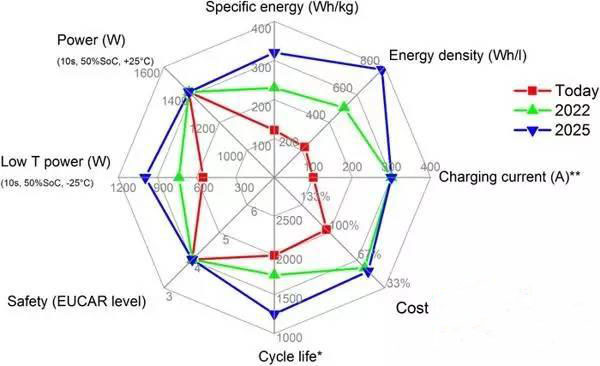

According to industry standards, when the battery capacity is attenuated to less than 80% of the rated capacity, the power battery is unsuitable for use in electric vehicles, and it is necessary to perform step-by-step utilization. When the battery capacity is attenuated to less than 20% of the rated capacity, dismantling and recycling are required. In the recycling process, the quality of each power battery is different, and the data retained is not necessarily complete. This requires a specific inspection, which undoubtedly increases the cost of the recycling process. In addition, different battery internal resistance characteristics, electrochemical characteristics, thermal characteristics are different, the battery's inconsistency and reliability can not be fully guaranteed, if there is a problem with the battery has not been detected, will give the subsequent recovery The process brings security risks. In addition, step-by-step utilization is an effective means of recycling, which can theoretically not apply to batteries on electric vehicles, and can be applied to solar and wind power generation systems, energy storage power stations, mobile base stations, and low-speed electric vehicles. However, China's technology is still lacking in the actual application of engineering, recycling, and recycling of technological equipment.

3. High cost of battery recycling, economic benefits

At present, the output value of power batteries in the domestic market is very high, but the economic benefits brought about by recycling are not so obvious. The electric vehicle resource network learned that a company that recycles waste lithium iron phosphate batteries using mechanical methods and wet methods costs 8540 yuan to recycle 1 ton of waste lithium iron phosphate power batteries, while the revenue from recycled materials is only 8110 yuan. Loss of 430 yuan. The reason why the economic benefits of power battery recycling are not high is that most of the power batteries in the domestic market are based on lithium iron phosphate and lithium manganese oxide, and the price of their raw materials is lower than that of other power battery materials. . In addition, the costs of labor and resource waste are also high during the recycling process. As mentioned earlier, due to the complexity of power battery manufacturing and processes, most of the recycling and dismantling processes need to be done manually, which requires a lot of labor costs. In addition, due to the manual dismantling, the process is also prone to errors, resulting in waste of resources and increased costs.

4. The recycling network is not yet complete, and the related standards are not punished

It is predicted that by 2020 China's power battery scrap will exceed 248,000 tons, about 20 times the amount of scrapped in 2016. In the face of the impending surge of battery recycling, China's recycling network is still not sound enough. The market has not established an effective recycling model and is not standardized enough. If the power battery is recovered by private companies that do not meet relevant standards and regulations, problems such as waste of resources and environmental pollution will easily occur. If these batteries, which have been recovered by private companies, flow into the market again, they will also bring security risks to people. Furthermore, even if the power battery is recycled by the relevant recycling company that meets the regulations, it will not receive any specific punishment if they do not follow the prescribed procedures and standards during the recycling process. Take the latest test of "Car Power Battery Recycling and Energy Surplus" implemented in February 2018, it only sets a standard for the detection of power battery recycling residual energy, but it has not established a specific and effective rewards and penalties. There is no guarantee that the relevant power battery recycling companies can fully comply with the relevant standards and regulations during the recycling process.

Before the arrival of power battery recycling boom, we should understand what obstacles will be encountered on the recycling road. Power battery recycling companies should also improve the relevant technologies and implementation standards for each issue so that China's power battery recycling tide can be safe, standardized, and effective.

RCCN WeChat QrCode

RCCN WeChat QrCode Mobile WebSite

Mobile WebSite