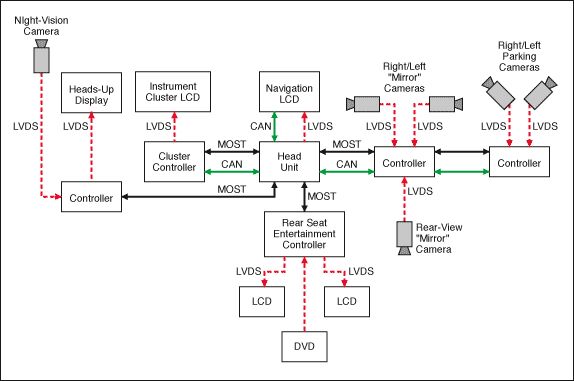

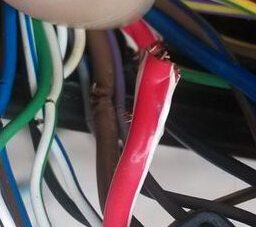

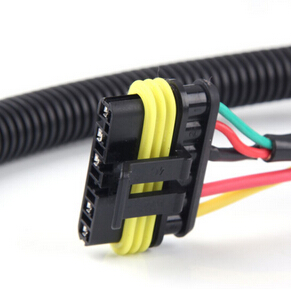

Harness is one of the products that have the fastest development in the electronic and information age industry, the largest market demand and the most convenient installation. In order to ensure the safe and reliable use of the harness, it must be strictly tested according to the product standard on the online harness production line or before the user uses it. Different industries have different requirements for test harnesses, and test items vary. In general, there are four items for harness testing:

1. Continuity test requires 100% correctness;

2. Harness impedance test, required to meet technical requirements;

3. The connection resistance of the harness connection wire and the connector;

4. Joints on the conductor of the bond strength test

Harness continuity and impedance testing are the most basic inspection items to ensure the quality and reliability of the harness. Through this inspection project, early failure products such as short circuit, open circuit, and miswiring can be eliminated. However, the detection methods of many units are still quite backward. Not only are they slow, they are inefficient, and workers are prone to fatigue, but they are also prone to false detections and missed inspections.

In recent years, a variety of new types of wire harness testers have been developed abroad, coupled with the corresponding detection tooling, after a plug and pass through the instrument's internal digital logic circuit, it can be very convenient, accurate and rapid wire harness detection. It has also been used in aerospace, aviation, transportation and many other industries. The only drawback is that such imported instruments are expensive, and many domestic manufacturers are discouraged and cannot be widely promoted. However, as long as we carefully study and re-select the existing originals for matching, such intelligent detection instruments will surely gain greater development space and applications in China.

RCCN WeChat QrCode

RCCN WeChat QrCode Mobile WebSite

Mobile WebSite