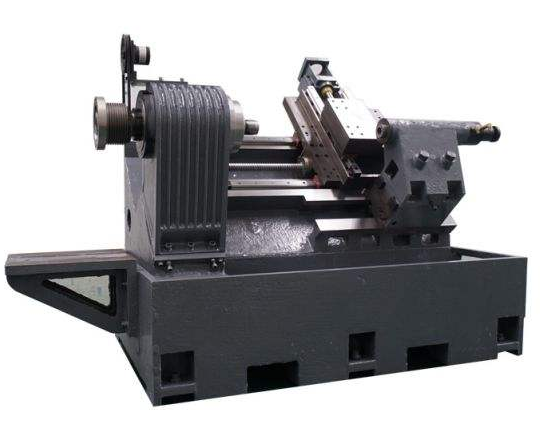

The machine is an industrial parent machine, a machine used to make machines, an important feature that distinguishes machines from other equipment. With the progress of industrialization, the manufacturing industry has put forward the requirements of high speed, precision and flexible manufacturing for the main machine. The machine tool has also been gradually developed into a high-speed CNC machine tool such as high-speed precision compound machining and five-axis linkage machining center by a common three- It realizes the processing of many processes such as milling, drilling, boring and so on in one loading of the workpiece, which not only has high processing precision but also improves the production efficiency due to the fast movement and accurate positioning.

As we all know, our country is the world's number one manufacturing power and the number one machine tool producer in the world. However, China has a big gap with the advanced international standards in the field of high-end manufacturing equipment.

Most noteworthy is that China's machine tool industry innovation and development and reliability levels significantly improved, machine tool industry standards and technical specifications gradually improved. Through the implementation of special projects, it has promoted the joint development of key domestic enterprises, universities and users, and actively organized the preparation of national / industrial standards for the reliability assessment of CNC machine tools, and promoted their application in the machine tool industry. The average MTBF of the machine tool has been generally raised to 1200 hours from the 400-500 hours before the special implementation. Some of the products have reached over 2000 hours and are close to the international advanced level. Special achievements formed a large number of technical standards and norms, the industry significantly enhanced its international competitive advantage, strong support for product development, but also to enhance the sustainable development of national equipment manufacturing industry play a protective role. In December 2016, the S-shaped test specimen proposed by our country for testing five-axis machine tools was approved by the International

Standard Committee and became the first standard in the design and testing of high-end CNC machine tools in our country, achieving zero breakthrough.

RCCN WeChat QrCode

RCCN WeChat QrCode Mobile WebSite

Mobile WebSite