Automotive wiring harness welding current production process mainly crimp and ultrasonic welding two: Crimp is the use of terminals will be stranded wire together to form a joint; ultrasonic welding is the use of ultrasonic vibration generated by the physical effects of the first combination of the thread. Ultrasonic used in automotive wire harness welding production, the earliest in Europe and the United States became popular, mainly due to the development of foreign ultrasonic metal welding technology. Comparison of two welding techniques:

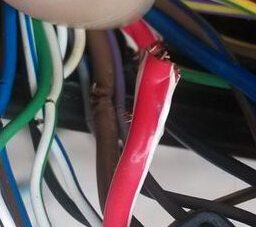

(A) crimping

Advantages: fast production speed; equipment is simple.

Disadvantages: metal stamping risk of rebound; under the conditions of oxidation and rust risk, all risks can lead to poor contact.

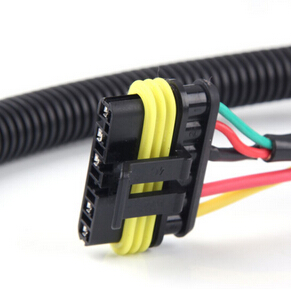

(B) ultrasonic welding

Advantages: Superior electrical connection characteristics (basic zero resistance); insensitive to the risk of oxidation and rusting under harsh conditions.

Disadvantages: equipment expensive; consumables are more expensive.

RCCN WeChat QrCode

RCCN WeChat QrCode Mobile WebSite

Mobile WebSite