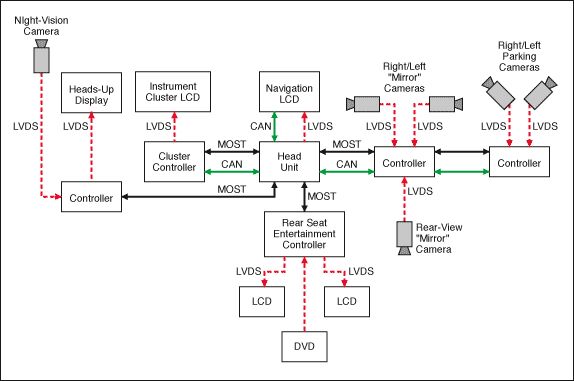

Automotive wiring harness processing Before the arrangement of wiring harness to be drawn in advance wiring harness, wiring harness and circuit diagram is not the same. The circuit diagram is an image that represents the relationship between the various electrical parts and does not reflect how the electrical parts are connected to each other regardless of the size and shape of the individual electrical components and the distance between them. The wiring harness diagram must take into account the size and shape of the various electrical components and the distance between them, but also how the electrical parts are connected to each other.

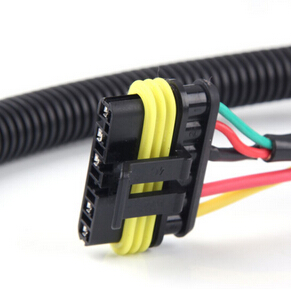

After the technician of the automobile wire harness processing made the wire harness cable board according to the wiring harness diagram, the workers cut the cable according to the requirements of the cable board. The main beam of the vehicle is generally divided into the engine (ignition, EFI, power generation, starting), instrumentation, lighting, air conditioning, auxiliary appliances and other parts, a main harness and branch harness.

A car main beam has a plurality of branch wiring harness, as if the tree pole and the same branches. The main wiring harness of the whole vehicle often takes the dashboard as the core part and stretches back and forth. Some automobile wiring harnesses are divided into the front harness (including instrument, engine, front lighting assembly, air conditioner and battery), the rear wiring harness Taillight assembly, license plate lights, trunk lights), awnings wiring harness (doors, dome lights, audio speakers) and so on.

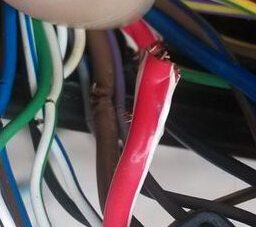

The ends of the car's wiring harness are marked with numbers and letters to identify the connections to the conductors. The operator sees that the signs are properly connected to the corresponding wiring and electrical equipment, which is especially useful when repairing or replacing the wiring harness. At the same time, the color of the wire is divided into monochrome lines and two-color lines, the use of colors are also provided, the general standard is the depot custom. China's industry standard is only the main color, such as the provisions of a single black dedicated to the ground wire, red monochrome for the power cord, can not be confused.

RCCN WeChat QrCode

RCCN WeChat QrCode Mobile WebSite

Mobile WebSite