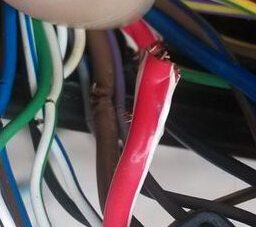

Common faults car lines are: poor connector, poor contact between the wires, open circuit, ground and so on. The company is located in:

There are several reasons for the production of electronic wiring harness:

(1) Natural damage

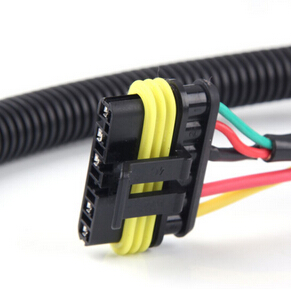

The use of the wiring harness exceeds the service life, so that the aging of the wire, the breakdown of the insulation layer, the significant decrease of the mechanical strength, causing short circuit, disconnection and grounding between the wires, resulting in burnout of the wire bundle. Harness terminal oxidation, deformation, resulting in poor contact, can cause electrical equipment can not work properly.

(2) Damage to the wiring harness due to electrical equipment failure

When the electrical equipment overload, short circuit, ground and other faults, may cause damage to the wiring harness. The company is located in:

(3) man-made fault

Assembly or maintenance of automotive parts, metal objects will be crushed electronic wiring harness, so that the wiring harness insulation rupture; improper wiring harness position; wiring leads to the wrong electrical equipment; battery positive and negative leads reversed; troubleshooting circuit, chaos , Chaos cut wire harness wire, etc., can cause the electrical equipment does not work properly, and even burn the wire harness.

RCCN WeChat QrCode

RCCN WeChat QrCode Mobile WebSite

Mobile WebSite