1, environmental performance

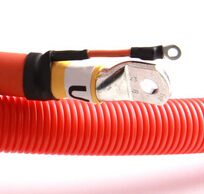

Temperature: the current maximum working temperature of the connector is 200 ℃ (except for a few high temperature special connector), the minimum temperature of -65 ℃. As the connector work, the current at the contact point to generate heat, resulting in temperature rise, it is generally believed that the operating temperature should be equal to the ambient temperature and contact temperature rise and. In some specifications, the maximum permissible temperature rise of the connector at rated operating current is specified.

Moisture resistance: moisture intrusion will affect the connection h insulation performance, and corrosion metal parts. Constant humidity test conditions for the relative humidity of 90% to 95% (according to product specifications, up to 98%), temperature +40 ± 20 ℃, test time by product, at least 96 hours. Alternating hot and humid test is more stringent.

Salt resistance: When the connector is working in an atmosphere containing moisture and salt, its metal structure and contact surface treatment layer may produce electrochemical corrosion, affecting the physical and electrical properties of the connector. In order to evaluate the ability of the electrical connector to withstand this environment, a salt spray test was specified. It is the suspension of the connector in the temperature controlled test chamber, with the specified concentration of sodium chloride solution with compressed air spray to form salt mist atmosphere, the exposure time by the product specification, at least 48 hours.

Vibration and Shock: Vibration and shock resistance is an important feature of electrical connectors that are particularly important in special applications such as aerospace and aerospace, railways and road transport. It is a test of the robustness of electrical connectors and the reliability of electrical contact An important indicator of sex. In the relevant test methods are clearly defined.

The impact test should specify the peak acceleration, duration and impact pulse waveform, and electrical continuity of the time.

Other environmental performance: According to the requirements, other environmental performance of the electrical connector is also sealed (air leakage, liquid pressure), liquid impregnation (resistance to specific liquids), low pressure and so on.

2, mechanical properties

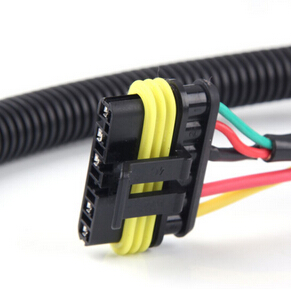

Insertion force is important for mechanical properties. Insertion force is divided into insertion force and pull out force, the two requirements are different. In the relevant standards have the maximum insertion force and the minimum separation force, which shows that from the use point of view, the insertion force is small, and the separation force is too small, it will affect the reliability of contact.

3, electrical performance

Insulation resistance measures the insulation performance between electrical connector contacts and between the contact and the enclosure, which is of the order of several hundred megohms to several gigahertz.

Dielectric strength or resistance to voltage, medium pressure, is to characterize the connector between the contacts or between the contact with the shell to withstand the rated test voltage capacity.

Other Electrical Performance Electromagnetic Interference Leakage attenuation is to evaluate the electromagnetic interference shielding effect of the connector. The electromagnetic interference leakage attenuation is to evaluate the electromagnetic interference shielding effect of the connector, usually in the frequency range of 100MHz ~ 10GHz.

RCCN WeChat QrCode

RCCN WeChat QrCode Mobile WebSite

Mobile WebSite