According to foreign media reports, engineers usually in the DC (DC) motor or AC (AC) motor to choose. Recently, the electronic rectifier (EC) motor has also joined the melee, the device helps to control the energy output, and enhance energy efficiency.

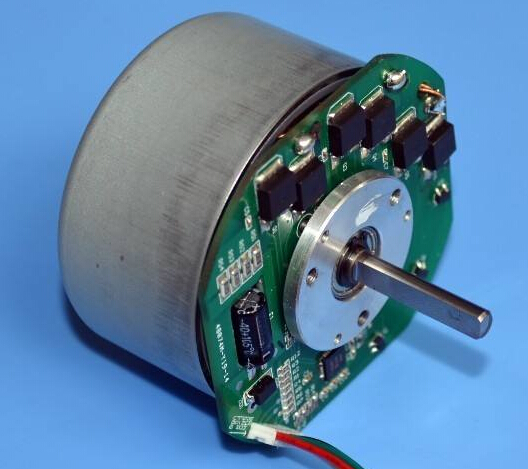

Engineers typically choose between DC motors or AC motors. Recently, the electronic rectifier (EC) motor has also joined the melee, the device helps to control the energy output, and enhance energy efficiency. The equipment is technologically advanced, is currently replacing the DC motor and AC motor, can achieve efficiency adjustment. Electronic rectifier motors and brushless DC motors are controlled by external electronic circuit boards to enhance control and efficiency.

Principle of DC and AC motor

DC motor with carbon brush and rectifier ring to change the rotating armature (rotating armature) within the current and magnetic field electrode direction, the internal rotor and fixed permanent magnet interaction will lead to motor rotation.

DC motor is limited by the brush system, the service life of 1000-1500 hours, if under extreme load, will be less than 100 hours. In the case of better working conditions, part of the motor operating life or will reach 15,000 hours. In addition, high-speed rotation is limited to rectification, usually the maximum speed per minute close to 10,000 times (RPM).

The efficiency of the DC motor is high, but there are some specific losses, and the factors that cause the loss are: initial resistance, brush friction and eddy current -current losses).

AC induction motors (AC induction motors) are used in a series of windings, and controlled by the AC input voltage, and its stator field (stator field), and then produce the rotor magnetic field. While the synchronous motor (synchronous motor) is another AC motor, its running power supply (supply frequency) high accuracy. When the current through the slip ring (slip ring) or permanent magnet, will produce a magnetic field. The synchronous motor runs faster than the induction motor, which is limited by the slip of the asynchronous motor.

The AC motor means that the operating value of the device will correspond to a specific point on the performance curve, which is consistent with the peak efficiency of the motor. If not in accordance with the corresponding value of the run, then the efficiency of the motor will fall sharply. The AC motor generates an induced current on the rotor, which in turn generates a magnetic field, which results in additional energy dissipation. Therefore, the efficiency of AC motor is not as good as DC motor. In fact, the DC motor efficiency than the AC motor more than 30%, because the permanent magnet will produce secondary magnetic field (secondary magnetic field).

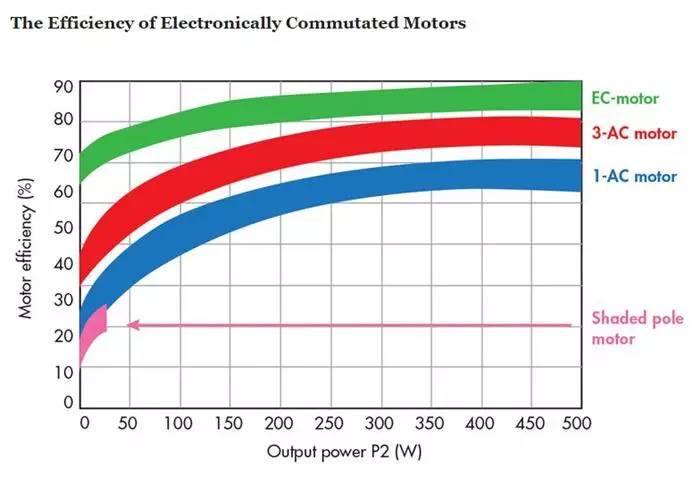

The above figure compares the motor efficiency of an electronic rectifier motor, a three-phase induction AC motor, a single-phase AC induction motor, and a shaded pole motor.

Introduction and Advantages of Electronic Rectifier Motor

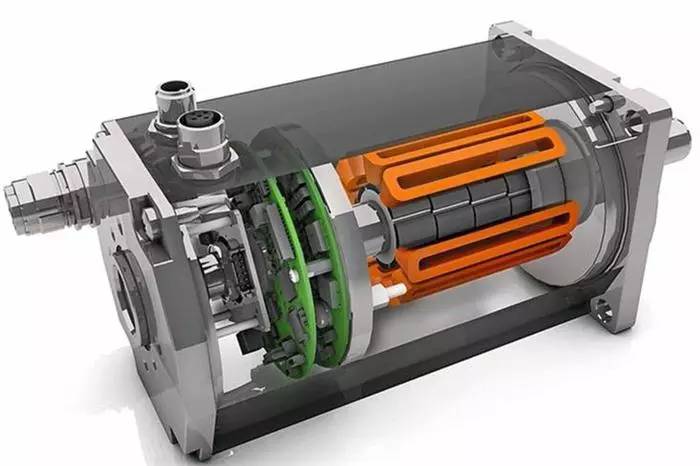

An electronic rectifier motor is a brushless DC motor controlled by an external electronic device. The electronic device may be an electronic circuit board or a variable-frequency drive. Mechanical commutation depends on the electronic circuitry, which can change the phase of the fixed winding to ensure that the motor rotates to provide the appropriate amount of armature current. If the current is transmitted in the correct direction over a precise period of time, a higher accuracy can be achieved. Since the rotational speed of the electrode is controlled by an external electronic device, there is no case where the synchronous speed is limited by the electronic rectifier motor.

The electronic rectifier motor has the following advantages: Since the motor has no brush, it does not produce Mars or because the brush causes the motor life to be shortened and does not waste energy because it uses electronic devices to control the stator, its performance and controllable Better sex. Compared to induction motors, the operating temperature is low. The smaller the size of the motor, the more space-saving, when the manufacturer uses external rotor (external rotor), and even save more space.

If the use of electronic rectifier motor, power distribution is also more clean. Brushless DC motor driven by a separate DC power supply, AC motor power will produce additional costs, and the design is more complex. The electronic rectifier motor can be connected directly to the AC mains supply, but it does not rely entirely on voltage or frequency, and small voltage variations do not affect the motor output.

If the electronic rectifier motor is compared with an AC hump motor or AC permanent-split capacitor motor, it is found that the efficiency range of the shunt motor is between 15% and 25% , The fixed-phase capacitor-type AC motor (permanent) is 30% -50%, and the efficiency of the electronic rectifier motor is in the range of 60% -75%.

Electronic rectifier motors can be used in low power output applications such as small fans, servo motors, motion control systems. A new method is being used to apply such motors to high-power output devices such as conveyor belts and condenser units.

In terms of speed control, the electronic rectifier motor has multi-speed control function, the speed controller is its standard parts. AC motors also offer most control functions and provide external speed controller options. External controller can adjust the AC motor transformer primary voltage (incoming voltage), can change the sine wave, the motor life will be affected, and lead to increased noise.

For the electronic rectifier motor, the rectifier circuit pulse width modulation (pulse-width modulation) is 4-20 mA, the voltage is 0-10 V, the motor speed control in the range of 10% -100%. Just use the integrated circuit, you can complete the electronic rectifier motor monitoring, the designer can provide the corresponding feedback. The electronic rectifier motor also provides soft start and low noise and motor temperature.

RCCN WeChat QrCode

RCCN WeChat QrCode Mobile WebSite

Mobile WebSite