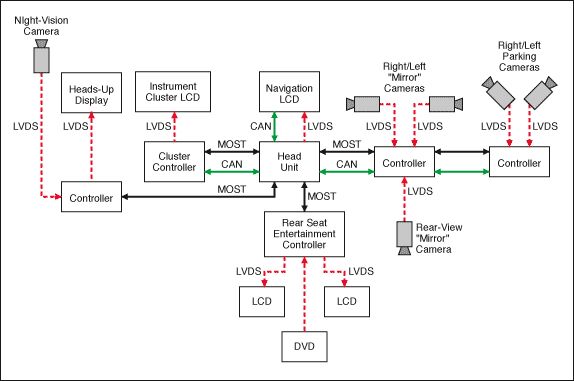

In modern cars, car wiring harness particularly large, electronic control system and wiring harness is closely related. Someone has played an image of the metaphor: If the computer, the function of the sensor and the implementation of components with the human metaphor, it can be said that the computer is equivalent to the human brain, the sensor is equivalent to the sensory organs, the implementation of components equivalent to motor organs, then the harness is the nerve and Blood vessels.

Automotive wiring harness is the main body of the car circuit, connecting the electrical and electronic components of the car and making it function, there is no wiring harness does not exist in the car circuit. At present, whether it is a luxury car or an economy ordinary car, the form of wiring harness is basically the same, are composed of wires, connectors and wrapping tape, it is necessary to ensure that the transmission of electrical signals, but also to ensure that the connection circuit The reliability of the supply of electrical and electronic components to the provisions of the current value to prevent electromagnetic interference to the surrounding circuit, and to exclude electrical short circuit.

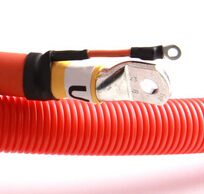

The car harness is functionally divided into two types of power lines that carry the drive actuator actuators (actuators) and the signal lines that carry the sensor input commands. The power line is a thick wire that carries a large current, and the signal line is a fine wire (optical fiber communication) that does not carry electricity. For example, the signal circuit has a conductor cross-section of 0.3 and 0.5 mm2.

In the motor, the implementation of the conductor with a cross-sectional area of 0.85,1.25 mm2, and the power supply circuit with a cross-sectional area of 2,3,5 mm2; and special circuits (starter, alternator, engine ground, etc.) 10,15,20 mm2 different specifications. The larger the cross-sectional area of the wire, the greater the current capacity. The choice of wire, in addition to considering the electrical performance, but also by the physical performance of the vehicle when the constraints, so its wide range of options. For example, a frequent open / close door on a taxi and a wire across the body should be made of a wire with good flexing performance. In the high temperature parts of the use of wire, generally use the insulation and heat resistance of vinyl chloride, polyethylene coated wire. In recent years, weak signal circuit using electromagnetic shielding lines are also increasing.

With the increase in the function of the car, the universal application of electronic control technology, more and more electrical parts, the wire will be more and more cars on the number of circuits and electricity significantly increased, the wiring harness becomes thicker and heavier The This is a big problem to be solved, how to make a large number of wiring harness in a limited car space how to more effectively rational layout, the car harness to play a greater function, has become a car manufacturing industry problems.

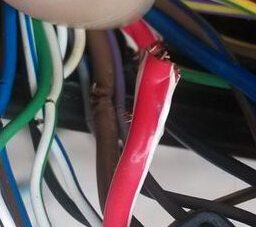

As people continue to improve comfort, economy and security requirements, the variety of electronic products on the car is increasing, and the failure rate of automotive wiring harnesses is increasing. This requires improved wiring harness reliability and durability and other properties, many people for the automotive wiring harness process and production are more interested in here Haoshi electronic on the car harness process and production of this knowledge to be a simple description, you only need Take a few minutes to read, you can generally understand.

After the two-dimensional product wiring out of the car harness, it is necessary to arrange the production process of the harness, the process is inseparable between the two services, so the author will combine the production and process of the car harness together.

The first station of the wire harness production is the open process. The accuracy of the opening process is directly related to the entire production schedule, in the event of errors, especially the open line size is short, will lead to all the station rework, time and effort to affect production efficiency. Therefore, in the preparation of the opening process is sure to be based on the requirements of the drawings to determine the wire size, stripping head size.

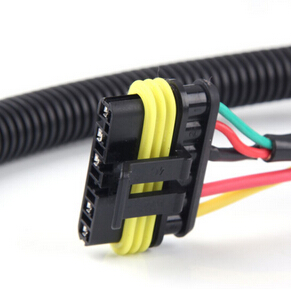

After the opening of the second station is the crimping process, according to the type of drawings required to determine the crimp parameters, the production of crimp operation instructions, for the special requirements of the need to indicate on the process file and training operators. For example: some wires need to wear through the jacket before crimping, it needs to first pre-installed wire and then returned from the pre-installed station and then crimping; there are punctured crimping with a dedicated crimping tool, which Kind of crimping method has good electrical contact performance.

Then is the pre-installed process, and first to prepare the pre-installed process operating instructions, in order to improve the efficiency of the assembly, the complex wiring harness should be set pre-installed, pre-installed process is reasonable or not directly affect the efficiency of the assembly also reflects a Technical level of technical staff. If the pre-installed part of the assembly of less or assembly of the wire path unreasonable will increase the total assembly staff workload, slow down the speed of the assembly line, so the process staff should always be at the scene constantly summed up.

The last step is the assembly process. Can be compiled according to the product development department design of the assembly board, design tooling equipment, material box size and all the assembly sheath and accessories number affixed to the material box to improve the efficiency of assembly. The preparation of the various parts of the assembly content and requirements, balance the entire assembly station to prevent the occurrence of a little workload is too large, pull down the entire assembly line speed situation. To achieve the balance of the station, the process staff must be familiar with each operation and on-site measurement of working hours, at any time to adjust the assembly process.

In addition, the wiring harness process also includes the preparation of material consumption quota schedule, man-hour calculation, worker training, etc., because the technical content value is not high, these are not elaborate. All in all, the automotive wiring harness in the car electronic technology content and quality, has gradually become an important indicator of vehicle performance evaluation. Car manufacturers for the choice of wire harness should pay special attention to, it is necessary to understand the next car wiring harness process and production.

RCCN WeChat QrCode

RCCN WeChat QrCode Mobile WebSite

Mobile WebSite