With the increasingly stringent domestic and international fuel consumption and emission regulations, the major OEMs began to focus on research and development with ultra-high fuel economy power system, taking into account the fuel consumption regulations and costs 48V weak hybrid technology has become a "new favorite." According to IHS "Global Insight" forecast, as of 2025, 48V hybrid car market share will account for 95% of the global mild hybrid market, almost half of the global total of hybrid cars. More importantly, China's future will become the main market for 48V technology, by 2025 will be about 8 million units of 48V models produced in China.

48V weak mixed for the future ready to go

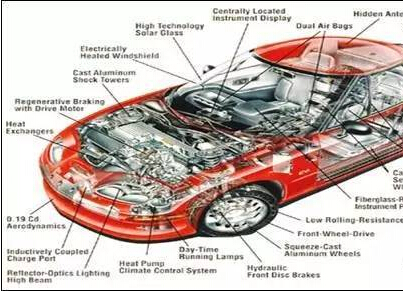

The original car equipped with 12V power supply voltage, because the 12V power battery power shortage, can not be a long time for the whole vehicle to provide power, so the use of automatic start and stop function, the engine will often re-ignition, and energy recovery is not sufficient, fuel Not thorough. However, equipped with 48V power supply system will have a higher battery capacity and higher voltage, you can more ease for the whole vehicle to provide energy. While high-voltage design to support the greater power of the starter, automatic start and stop the reaction speed will be further enhanced. Start with the motor starting, taxiing with the motor recovery of energy, full throttle motor can also help output power. And air conditioning can also use the motor, after the flame will not stop working. In addition, the 48V weak mixing system in addition to optimizing the current automatic start and stop function, but also has engine downtime, navigation and braking energy recovery, acceleration and electric cruise function.

48V and eBooster®: Strong combination to create a strong driving force

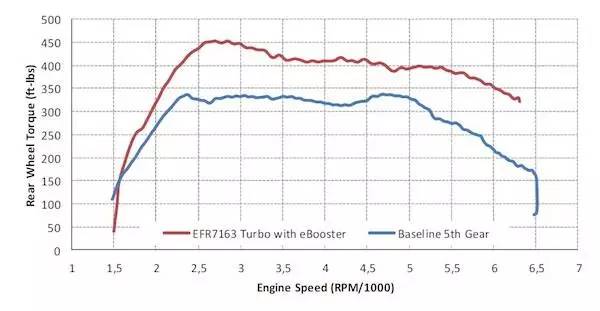

48V of eBooster® power is 5kW, the maximum speed of 72,000 rpm, up to 90% of the maximum speed to be 230 milliseconds. Instantaneous can reach 6.2kW, in continuous work, can reach 2-3kW. BorgWarner did not make the power of eBooster higher because of the need to consider the overall efficiency of the system. Increase the pressure ratio is not equal to increase the amount of electricity can be, if the pressure ratio caused by the use of the whole system in the low efficiency range, then it means to consume more electricity at the expense of. So BorgWarner is a comprehensive consideration of the power range and the electronic supercharger pressure ratio. At the same time, the application of eBooster's 48V system can increase fuel efficiency by up to 35%, can significantly reduce emissions.

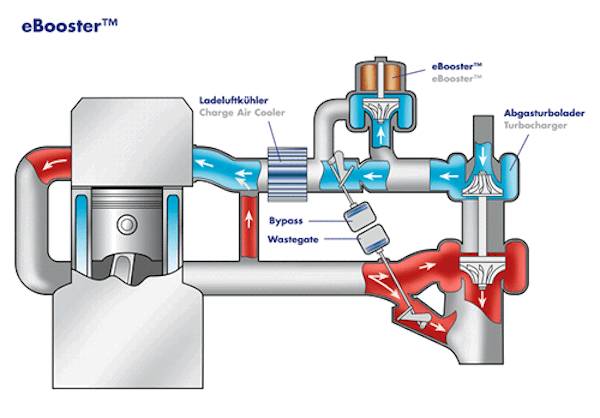

EBooster® and turbocharger: the perfect combination of driving experience

Drive technology and turbocharger work together, according to the demand to provide pressurization at the same time can also effectively avoid the phenomenon of turbulence can be perceived. The traditional turbocharged power system to bring the driver is the biggest trouble is the turbine hysteresis. EBooster® technology solves turbo hysteresis without sacrificing engine power consumption: the engine is driven by eBooster® when the engine is running at low speed and the exhaust flow is also impeller with a turbocharger Work, to provide pressurization. Wait until the exhaust flow becomes larger, through the exhaust gas to drive another turbocharger involved in the work. The elimination of turbo hysteresis gives the driver a stronger power experience that can reach the maximum torque in a shorter period of time. As the eBooster® is driven by the motor, the maximum speed of the electronic booster can be reached by 230 milliseconds. The vehicle's acceleration performance and control feeling has been significantly improved. In addition, eBooster® itself is small and very lightweight, and has a good NVH effect.

The combination of eBooster® and turbocharger is equivalent to a two-stage turbocharger. In this process, eBooster® maintains a continuous boost of 2-3 kW when the engine is running at high speed to assist the turbocharger. This not only greatly improves the engine torque at each speed, but also for the engine to provide more possibilities for miniaturization, thereby reducing fuel consumption. In the process of matching the engine, eBooster® has a very good effect at low engine speeds, and the turbocharger can be more focused on the engine's high speed when matched to the engine, save fuel consumption while boosting driving pleasure and Reduce emissions.

Responding to increasingly stringent emission standards to help the engine miniaturization and low speed

With the domestic CAFC regulations tightened year by year, 2020 will require all car prices to reach 5.0L / 100 km within the target limit. The miniaturization and low speed of the car to enhance fuel economy, reduce emissions of important technical dependencies. With the eBooster®, a range of gearboxes such as gearboxes and differentials can be matched to the engine to allow the engine to operate at a lower speed per minute in a given high speed road condition. For example, when the car is accelerating or climbing, the use of eBooster® does not require downshift to provide greater torque directly at high gear speeds, resulting in low engine speed to reduce fuel consumption and emissions. In addition, eBooster® can also help the engine to reduce the size, so that the small engine torque and power comparable to large-scale engine. The first item produced by eBooster® Daimler's S Class example: it was originally used 4.8L V8 engine, the maximum power of 320kW. However, after adding the eBooster®, the engine becomes 3.0L, the I6 engine with the same power.

The future of turbocharging

The future of turbochargers will evolve from eBooster® to eTurbo®. With the same philosophy, eTurbo® is an energy-assisted integrated motor turbocharger that BorgWarner is developing. The biggest challenge for this product is to achieve the concept of bearings and integrated motor, and the heavy integrated motor in the turbocharger at high speed while achieving high-speed operation. At present, BorgWarner has produced a test prototype, and many European and American OEM have already got the prototype to carry out the experiment. I believe this will be a future-oriented solution, in a short period of time to get the maximum torque for the driver to bring more fun driving experience.

Forced by more and more heavy environmental pressure and fuel consumption restrictions, the future of China's car must move towards a more clean, efficient transformation and upgrading of the road. The face of 12V system fuel-efficient effect, motor and battery performance limitations and other issues, the new 48V system came into being. It is able to effectively improve the fuel economy and reduce emissions while providing long-lasting momentum, which is currently recognized on the market as the most effective response to the forthcoming implementation of the national six emission standards. The efficient Turbocharging Solution 48VeBooster®, developed by BorgWarner, has an ultra-high fuel economy that can help drive small and low-speed engines. At present, many domestic depot and BorgWarner eBooster® electronic supercharger technology cooperation talks are in full swing.

RCCN WeChat QrCode

RCCN WeChat QrCode Mobile WebSite

Mobile WebSite