automotive wiring harness crimping process

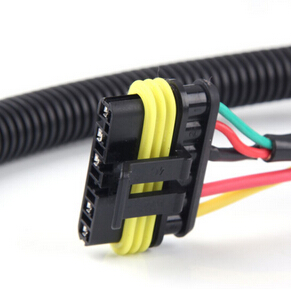

1,After the opening of the second production station, according to the type of drawings required to determine the crimp parameters, the production of crimp operation instructions, for the special requirements of the need to indicate in the process file and training operators. For example: some wires need to wear through the jacket before crimping, it needs to first pre-installed wire and then returned from the pre-installed station and then crimping; there are punctured crimping with a dedicated crimping tool, which Kind of crimping method has good electrical contact performance.

In order to improve the efficiency of assembly, the complex wiring harness should set the pre-installed station, the pre-installation process is reasonable or not directly affect the efficiency of the total assembly also reflects a process personnel. In order to improve the efficiency of the assembly, The level of technical level. If the pre-installed part of the assembly or assembly of the wire path is unreasonable to increase the total assembly staff workload, slow down the speed of the assembly line so the process staff to stay in the field constantly sum up experience, so as to prepare a reasonable production process The

3, the car wiring harness assembly process According to the product development department design of the assembly board, design tooling equipment, material box size and all the assembly sheath and accessories number affixed to the material box to improve the assembly efficiency. The preparation of the various parts of the assembly content and requirements, balance the entire assembly station to prevent the occurrence of a little workload is too large, pull down the entire assembly line speed situation. To achieve the balance of the station, the process staff must be familiar with each operation and on-site measurement of working hours, at any time to adjust the assembly process. Harness process also includes the preparation of material consumption quota schedule, working hours estimates, workers training.

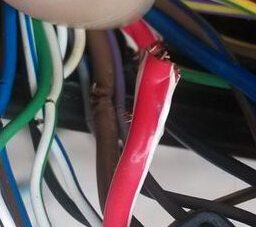

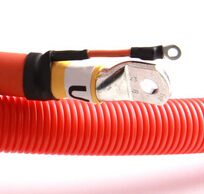

4, the test of the wiring harness in order to ensure the quality of the wiring harness, wiring harness inspection also runs through each link in the production, because the main wiring harness to play a connection so the terminal crimp demanding, contact or a terminal at the same time connect two or When more than two wires are used, the cross section is selected to measure the tension.

Wire harness in the final inspection of the main inspection size and conduction line energy, the tape can be used to detect the size of each branch of the wiring harness to meet the requirements of the drawings; In addition to a very simple wiring harness, the continuity test to use the guide,

It is a pre-set a good test procedures for computer testing equipment. In the detection of the harness to be detected before the number and name into the corresponding wiring harness in accordance with the corresponding jack after the connection can be carried out circuit continuity test, if any failure can be displayed through the computer screen to Prompt to detect personnel.

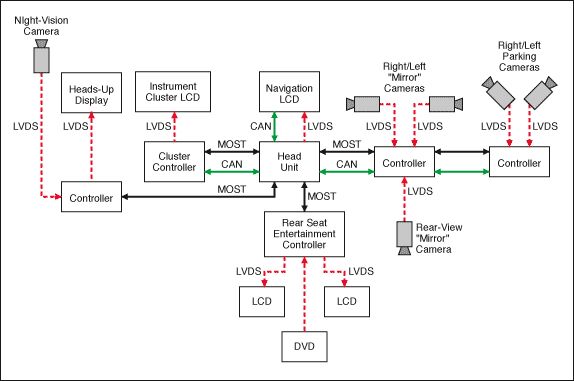

5, bus technology The world's common car bus control methods are two: LONWORKS bus and CAN bus. Regardless of which purpose is to improve the harness reliability, reduce the number of traditional wires, to achieve the digital signal transmission circuit.

RCCN WeChat QrCode

RCCN WeChat QrCode Mobile WebSite

Mobile WebSite