Automotive wiring harness is the main body of the car circuit, there is no wiring harness does not exist in the car circuit. At present, whether it is a luxury car or an economy ordinary car, the form of wire harness is basically the same, are composed of wires, connectors and wrapped tape.

Automotive wire, also known as low-voltage wire, it is not the same as ordinary household wires. Ordinary household wire is copper single core wire, a certain hardness. The car wires are copper multi-core cord, some soft lines like hair, a few or even dozens of soft copper wire wrapped in plastic insulated tube (PVC), soft and not easy to break.

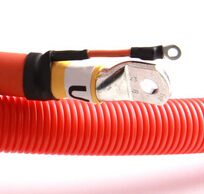

Automotive wiring harness commonly used specifications with a nominal cross-sectional area of 0.5,0.75,1.0,1.5,2.0,2.5,4.0,6.0 square millimeter of the wires, each of which has a load current allowed, equipped with different power equipment Of the wire. The specification line is suitable for the lamp, the indicator light, the door lamp, the dome light, etc .; The 0.75 specification line is suitable for the license plate lamp, the front and rear small lamps, the brake lights and so on; 1.0 The specification line is suitable for turning lights, fog Lights, etc .; 1.5 specifications for headlights, speakers, etc .; main power lines such as generator armature line, ground wire and other requirements 2.5 to 4 square millimeters of wire. This is only refers to the general car, the key depends on the maximum load current value, such as battery grounding line, the cathode power cord is a dedicated car wire alone, their diameter is relatively large, at least a dozen square millimeters Above, these "giant" wire will not be included in the main harness.

In front of the wiring harness in advance to draw harness map, wiring harness and circuit schematic is not the same. The circuit schematic is an image representing the relationship between the electrical parts, which does not reflect how the electrical pieces are connected to each other, regardless of the size of each electrical element and the distance between them. And the wiring pattern must take into account the size of each electrical components and the distance between them, but also reflect the electrical parts are connected between each other.

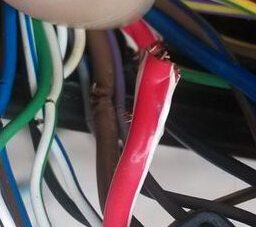

Harness factory technician made according to the wiring harness wiring harness after the board, the workers in accordance with the provisions of the cable board to intercept the cable. Vehicle main harness is generally divided into the engine (ignition, EFI, power generation, starting), instrumentation, lighting, air conditioning, auxiliary appliances and other parts, the main harness and branch wiring harness. A vehicle main harness has multiple branch harnesses, just as tree branches and branches. Vehicle main harness is often the instrument panel as the core part, before and after the extension. Due to the length of the relationship or easy assembly and other reasons, some of the car's wiring harness is divided into front harness (including instrumentation, engine, front light assembly, air conditioning, battery), rear harness (tail light assembly, license plate lights, luggage lights) Wiring harness (door, dome light, audio speakers) and so on. Each end of the harness will be marked with numbers and letters to indicate the connection object of the wire. The operator sees the sign correctly connected to the corresponding wire and electrical device, which is particularly useful when repairing or replacing the wiring harness. At the same time, the color of the wire is divided into monochrome and two-color line, the use of color is also provided, generally the factory custom standards. China's industry standard is only the main colors, such as the provisions of a single black dedicated to the line, red monochrome for the power cord, can not be confused.

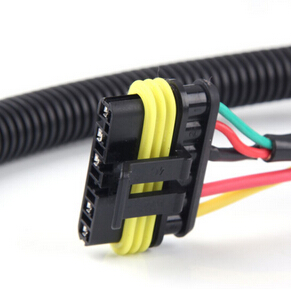

Harness wrapped with woven or plastic tape, for security, processing and maintenance convenience, woven wiring has been eliminated, it is now wrapped with a sticky plastic tape. Wiring harness and wiring harness between the wiring harness and the connection between the electrical parts, the use of connectors or lugs. The connectors are made of plastic and have plugs and sockets. Wiring harness and harness between the plug with the connector, wiring harness and electrical connection between the use of connectors or wire ear.

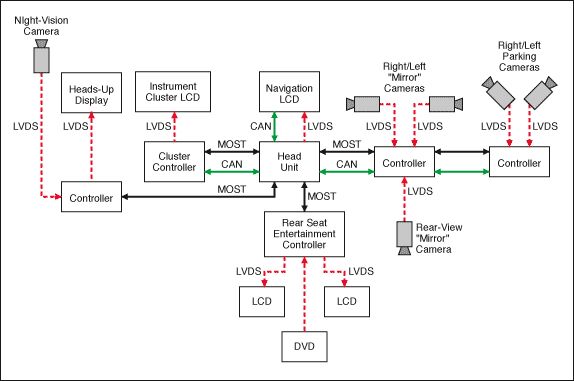

With the increase in the function of the car, the universal application of electronic control technology, more and more electrical parts, wires will be more and more, the wiring harness will become more rough and heavier. So the advanced car on the introduction of the CAN bus configuration, the use of multi-channel transmission system. Compared with the traditional wiring harness, multi-channel transmission device greatly reduces the number of wires and connectors, wiring easier.

RCCN WeChat QrCode

RCCN WeChat QrCode Mobile WebSite

Mobile WebSite