Cell

1 inspection content and manner

1) battery chip manufacturers, packaging (packaging and packaging), appearance, size, electrical properties, solderability, gate line printing, the main line of wire tension, cutting electrical performance uniformity. (The battery sheet in the unopened before the shelf life of one year)

2) sampling (according to the incoming two thousandths), electrical performance and appearance and solderability in the production process full inspection.

2 inspection tool equipment

Monolithic tester, vernier caliper, electric iron, rubber, blade, Rally, laser dicing machine.

3 required materials

Coated with tin, flux.

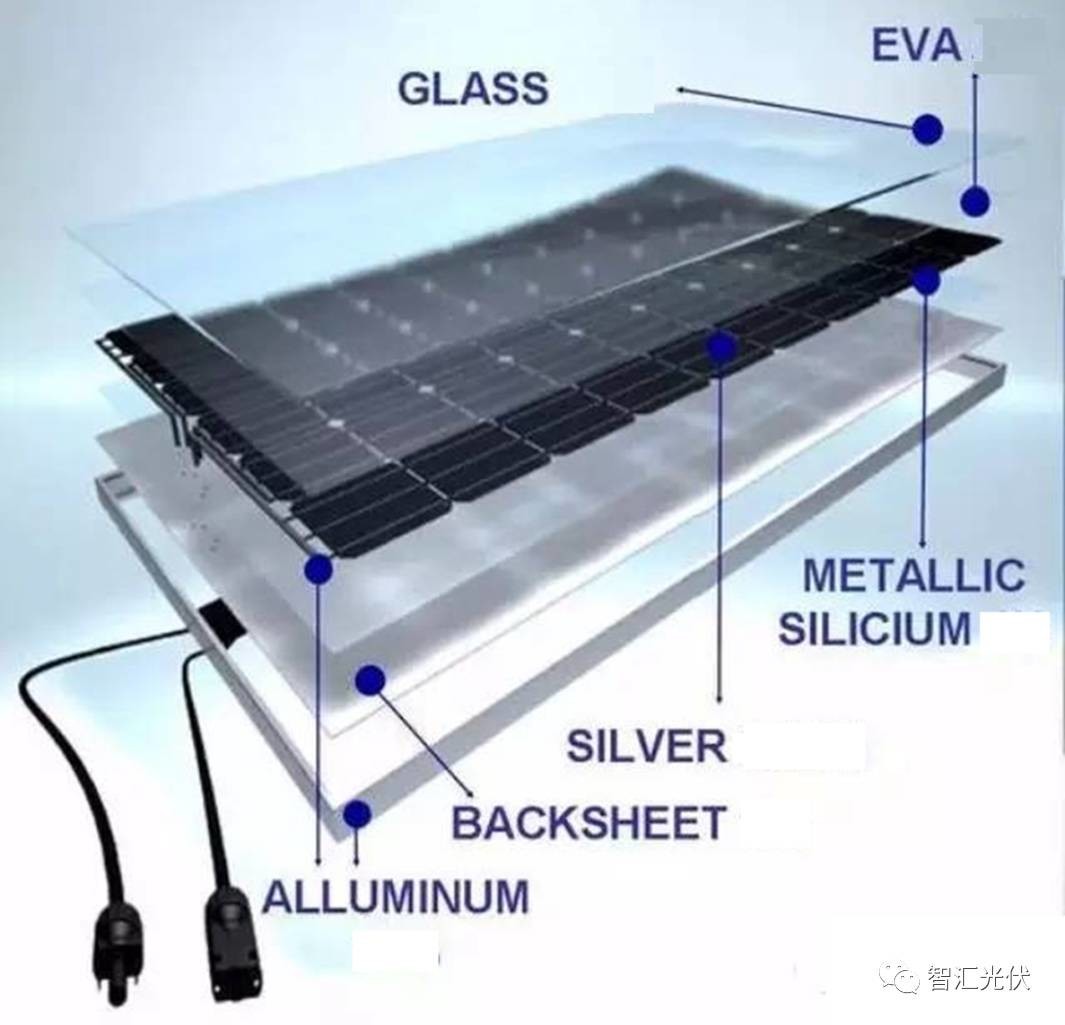

Figure 1: The basic structure of PV modules

Figure 1: The basic structure of PV modules4 test method

1) Packing: good, visual inspection.

2) Appearance: meet the requirements of the purchase contract.

3) Size: measured with a vernier caliper, the results meet the manufacturers to provide the size of ± 0.5mm

4) Electrical performance: test with a single tester, the results of ± 3%.

5) Solderability: 320-350 ℃ temperature of the normal welding, welding the main grid after leaving a uniform solder layer for qualified. (To ensure that the experimental use of tin tape and flux with solderability)

6) grid printing: with rubber in the same position repeatedly rub back and forth 20 times, do not fall off as qualified.

7) Main grid wire tension: the chain is welded into a △, and then use the tensile test, the results are greater than 2.5N.

8) uniformity of electrical properties after cutting: a number of copies of the battery chip with a laser dicing machine to test the electrical properties of each piece to maintain the error in ± 0.15W.

5 inspection rules

The above content of the full inspection, if there is a non-compliance with the requirements of the batch of five thousandth of the test. If it does not meet the contents of 4), 5), 7), 8), it is determined that the batch is unqualified.

Coated with tin

1 inspection content and manner

1) manufacturers, specifications, packaging, shelf life (six months), appearance, thickness uniformity, solderability, breaking rate, snake-like bending and tensile strength.

2) each incoming full inspection (plate), the appearance of the production process full inspection.

2 inspection tool equipment

Steel ruler, vernier caliper, iron, vise, rally.

3 required materials

Battery chip, flux.

4 test method

1) outside the packaging visual good, shelf life, specifications models and manufacturers.

2) Appearance: Whether the surface of the painted tin belt with black spots, tin layer is not uniform, twisted and other undesirable phenomena.

3) Thickness and specifications: According to the geometric size of the supply inspection, width ± 0.12mm, thickness ± 0.02mm as qualified.

4) Solderability: with the battery test method

5) Breaking rate: take the length of the same specifications of the coated tin with 10, bending 180 ° in one direction, the number of break should not be less than 7 times.

6) serpentine curvature: the tin tape will be pulled out of the length of 1 meter close to the ruler, measuring the maximum distance from the ruler, the maximum <3.5mm.

5 inspection rules

The above content of the whole inspection, if there is a test does not meet the re-inspection requirements Such as still does not meet 2), 4), 5) the contents of the batch is judged to be unqualified.

EVA film glue

1 inspection content and manner

1) manufacturers, specifications models, packaging, shelf life (six months), appearance, thickness uniformity, and glass and backlash peel strength, cross-linking degree.

2) incoming sampling, the production process of the peel strength and cross-linking degree in the sampling, appearance of the whole process of reproduction.

2 inspection tool equipment

Tape ruler, vernier caliper, wallpaper knife, Rally, scissors, 120 mesh wire mesh, cross-linking tester, oven, electronic scale

3 required materials

TPT backplane, small glass, xylene, antioxidant.

4 test method

1) packaging visual good, confirm the manufacturers, specifications and shelf life.

2) visual appearance, to confirm the EVA surface without black spots, stains, no wrinkles, holes and other phenomena.

3) According to the geometric dimension provided by the supplier, the width is ± 2mm and the thickness is ± 0.02mm.

4) Thickness uniformity: take the same size of 10 film weighing, and then compare the weight of each film, the maximum for the minimum must not exceed 1.5%.

5) Peel strength: According to the manufacturers to provide laminated parameters after the test, EVA and glass, EVA and the peel strength of the backplane. (After cooling)

A.EVA and TPT peel strength: with a wallpaper knife in the middle of the back plate to open the width of 25px, and then pull the TPT with the rally, eval, pull more than 35N qualified.

B.EVA and glass peel strength: the same method, with one end of the Rally clamped EVA, the other end of the fixed glass, pull more than 20N qualified.

6) cross-linking test: see cross-linking test method, the test results between 70% -85% qualified.

5 inspection rules

The above content of the whole inspection, if there is a test does not meet the re-inspection requirements If still does not meet 2). 5). 6) item content is judged to be unqualified.

Backplane

1 inspection content and manner

1) manufacturers, specifications models, packaging, shelf life (one year), appearance, bonding strength with EVA, backplane level of bonding strength.

2) incoming sampling, the production process on the peel strength and bonding strength in the sampling, appearance reproduction process full inspection.

2 inspection tool equipment

Tape measure, vernier caliper, wallpaper knife, Rally meter.

3 required materials

EVA, small glass.

4 test method

1) packaging visual good, confirm the manufacturers, specifications and shelf life.

2) visual appearance, to confirm the back surface without black spots, stains, no wrinkles, holes and other phenomena.

3) According to the geometric dimension provided by the supplier, the width is ± 2mm and the thickness is ± 0.02mm.

4) adhesion strength with EVA: method with EVA and TPT peel strength.

5) Bonding strength of the backplane level: with the blade to open the back plate sandwich, clamping side, the other side with a tensile test results greater than 20N.

5 inspection rules

The above content of the whole inspection, if there is a test does not meet the re-inspection requirements If still does not meet 2). 4). 5) item is judged to be unqualified.

Tempered glass

1 inspection content and manner

1) manufacturers, specifications models, packaging, appearance, tempered strength, thickness and size, and EVA peel strength.

2) incoming sampling, the appearance of the whole process of reproduction.

2 inspection tool equipment

Tape measure, caliper, 1040g steel ball.

3 required materials

EVA, backplane.

4 test method

1) packaging visual good, confirm the manufacturers, specifications models.

2) Dimensions (L * W * D):

Tempered glass standard thickness of 3.2mm, allowing deviation of 0.2mm.

Length and width allowable deviation of 0.5mm, diagonal tolerance of 0.7mm

3) visual appearance:

Tempered glass allows a length of no more than 10mm on each side of the glass, extending from the edge of the glass to the surface of the glass plate by no more than 2mm, extending from the surface of the glass to the other side of the glass does not exceed one-third of the thickness of the glass.

Tempered glass is not allowed to have a concentration of less than 1mm. For lengths greater than 1mm

Do not allow stones, cracks, missing angle occurs.

Tempered glass surface allows the width of less than 0.1mm per square meter, the length of less than 50mm scoring number of not more than four. Within the width of 0.1-0.5mm per square meter length less than 50mm scratches no more than one.

Tempered glass does not allow wave bending, bow bending does not allow more than 0.2% of the side length. (The incoming sample is placed on the platform, measuring the maximum distance from the table)

4) peel strength with EVA: the same with the EVA peel strength test method.

5) Tensile strength: to come to six samples of the test, the glass placed on the test stand, with the ball from the glass 1-1.2 meters, so that the ball free to fall on the glass, the glass is not broken for the qualified.

5 inspection rules

The above content of the whole inspection, there is a do not meet the inspection requirements are re-check. If there is still no match 2). 3). 4) 5) check the content, then determine the batch for the unqualified incoming.

Aluminum profiles

1 inspection content and manner

1) Packaging, size, surface hardness, oxide film thickness, profile bending, appearance, material, profile and corner code matching.

2) incoming sampling, the appearance of the whole process of reproduction.

2 inspection tool equipment

Tape measure, vernier caliper, platform.

3 required materials

Coated with tin, flux.

4 test method

1) packaging visual good, confirm the manufacturers, specifications models.

2) Size: According to the geometric dimensions provided by the supplier to measure the width of + 1mm, length + 1mm

Allowable deviation of wall thickness ≤ 0.5mm

3) Appearance: no surface oxidation, the whole root 0-12.5px scratches shall not exceed 2; 0.5-25px scratches the number of no more than 1, does not allow more than 25px scratches.

4) Profile bending: the expected floor of the installation platform with the maximum distance of not more than 0.2% of the long side of the pass.

5) profiles and angle code matching: take a set of profiles assembled, the gap <1mm qualified.

6) by the supplier to provide surface hardness (> 12), oxide film (> 10um), material.

5 inspection rules

The above content of the whole seizure, there is a non-compliance with the inspection requirements, the batch of product re-inspection, if there is still not meet 2). 3). 5) inspection requirements, to determine the batch for the unqualified incoming.

Silica gel

1 inspection content and manner

1) manufacturers, specifications models, packaging, shelf life, appearance, surface dry time, elongation, and the back of the bonding test.

2) incoming sampling, production process tracking test.

2 inspection tool equipment

Glue gun, stopwatch, ruler, rally meter.

3 required materials

All kinds of backplane.

4 test method

1) to confirm the incoming manufacturers, specifications models, packaging, durability period.

2) Appearance In bright environment, the product will be squeezed into a thin strip for visual inspection, the product should be delicate ﹑ uniform paste or viscous liquid, no caking ﹑ gel ﹑ bubble. The color is generally white or creamy, non-irritating odor.

3) the dry time will be the product with a glue gun in the experimental board into a thin strip, immediately start the time, until the fingers touch the tape appears when the fingers do not stick, record from extrusion to non-stick time (10min ≤ time ≤ 30min)

4) elongation: in the experimental board evenly hit a silicone, to be fully cured (recording curing time, the thickness of the silica gel, the original length, the length of the stretch) for tensile test results ≥ 300%.

5) Adhesion test: in the different backplane on the play three silica gel, after curing to observe the bond with the tensile test, record the value. (The result is greater than 10N).

5 inspection rules

The above content of the whole inspection, there is a do not meet the inspection requirements are re-check. If there is still not meet the 2), 3), 4), 5) inspection requirements, determine the batch for the unqualified incoming.

Junction Box

1 inspection content and manner

1) manufacturers, specifications models, appearance, connector tension, lead bayonet bite force, diode discipline bite force, box bite force, diode voltage test.

2) incoming sampling, production process tracking test.

2 inspection tool equipment

Rally, pressure test.

3 required materials

Coated with tin.

4 test method

1) to confirm the junction box manufacturers, specifications models

2) Appearance: Check the appearance of any defects, logo (should be non-wiped), and the number of diodes and junction box defects.

3) connector tension: the connector connected to the junction box, and then clamp the junction box, with the tensile test (tension> 10N) for the qualified.

4) Lead bayonet bite force: the convergence of the tape into the bayonet, with a rally to withstand the application of tension> 40N for qualified.

5) box bite force: continuous launch three times, still need special tools to open for qualified.

6) Diode withstand voltage: with a pressure tester test (1000VDC)

5 inspection rules

The above content of the whole inspection, there is a do not meet the inspection requirements are re-check. If there is still not meet the 2), 3), 4), 5), 6) inspection requirements, determine the batch for the unqualified incoming.

RCCN WeChat QrCode

RCCN WeChat QrCode Mobile WebSite

Mobile WebSite