At present, the Jiangsu Datang project in the hoisting is progressing in an orderly manner according to the construction schedule and the owner's delivery requirements. As of the date of publication, 38 units have been hoisted. “The average speed of hoisting of offshore units is about 5 units/month. In the project, we completed the hoisting of 9 units in June, and started the reversal of the 10th unit tower, blades and main engines in the same month. Chong Ten, refreshed the record of the number of hoisting units of offshore wind turbines in China in one month.” A Mingyang intelligent project manager with many years of experience in hoisting offshore wind power projects said.

So how was the record born?

Carefully planned to ensure that projects are delivered on demand

Blacksmith need its own hardware. The birth of the project's hoisting record is inseparable from the support of Mingyang's intelligent delivery capability.

First of all, according to the project construction plan, Mingyang Intelligent will evaluate the foundation pile installation and construction ship equipment in advance in January and February, and pre-arrange the production based on the advantages of multi-base and multiple factory synchronization operations, and reserve the main engine and large components. Guarantee the timely delivery of products and on time delivery. It is worth mentioning that, considering the long distance between the terminal and the aircraft position used by the project, Mingyang Intelligent has built a temporary reserve transfer storage facility at the dock and parked between the terminal and the aircraft site. The transport vessel can transport another set of units from the dock while reversing according to the hoisting situation, ensuring the timeliness of delivery.

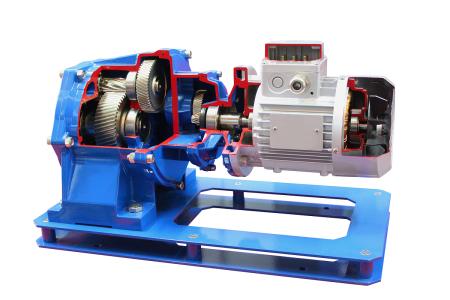

Secondly, based on the semi-direct drive technology route, Mingyang Intelligent has cultivated a mature and stable supply chain. This “specialized store” supply model makes the supply chain system of key components rarely compete with the industry. Moreover, the gearbox, generator and hydraulic system modules of Mingyang intelligent semi-direct drive unit adopt standard universal connection, which can realize free switching in the same series of units, and supply chain resources can be flexibly deployed inside to realize resource sharing.

In addition, on the logistics side, Mingyang Intelligent also formulated the “N+2” shipping plan, and formulated the logistics transportation plan two months in advance, and closely implemented with the site. Through timely adjustment of material delivery and shipping plans, risk management and preventive measures are taken in advance to ensure the reliability of delivery.

Small and exquisite, the advantage of the unit helps to lift

The construction progress of offshore projects is greatly affected by the structure, space and advanced nature of the working vessels. The size and weight of the main unit are different, and the requirements for installing ships, spreaders and tooling are also different. Taking the spreader as an example, the complexity of its design is directly related to the cost, safety and efficiency of lifting. The greater the weight of the hoisting components, the higher the design complexity of the spreader and the higher the cost.

The cabin weight of the Mingyang Intelligent MySE model is about one-third lighter than the other technical units of the same single-unit capacity, and the length is nearly half. The small and exquisite unit advantage allows the limited working platform space to be utilized to the extreme, so that the main unit lifting and the impeller pair can be simultaneously performed during the lifting process. The advantages of the technical route make the MySE model also help the owner to save costs while improving the lifting efficiency.

Multi-party linkage, difficult to overcome the progress

In the process of unit delivery, on the one hand, Mingyang intelligent project management personnel carefully planned the delivery plan, delivery plan, delivery schedule, lifting process and emergency response of the unit and its large components in strict accordance with the company's project management mechanism. Taking the tower as an example: according to the characteristics of the project, Mingyang intelligent advance layout and multi-point supply, and the three towers factories organize production according to the design requirements. During the period, Mingyang Intelligent will continuously supervise, test and assemble the tower factory to ensure the continuity of supply.

On the other hand, the owner selects a special person to conduct daily statistical analysis of material supply and production progress. At the same time, the construction plan is reasonably arranged in conjunction with meteorological changes, and the construction unit is urged to strengthen the production schedule control, and the process and materials are connected to ensure the smooth construction of the sea.

Offshore engineering is a complex system engineering. Mingyang has been deeply cultivating China's offshore wind power for decades. It insists on technological innovation as the core driving force, adhering to the concept of “product birth decided to live”, using systematic thinking from the beginning of product design. It injects high-reliability genes into the entire lifecycle of manufacturing, delivery, commissioning, and networking. Mingyang Smart is committed to building a superior product and service, and is committed to maximizing the return on investment in wind farms and reducing the cost of electricity. At present, Mingyang Intelligent has prepared for the upcoming large-scale development and mass delivery of offshore wind power. It will meet the needs of the owners with advanced technology, high-quality products and a stable supply chain system to ensure the maximum benefit of the owners.

RCCN WeChat QrCode

RCCN WeChat QrCode Mobile WebSite

Mobile WebSite

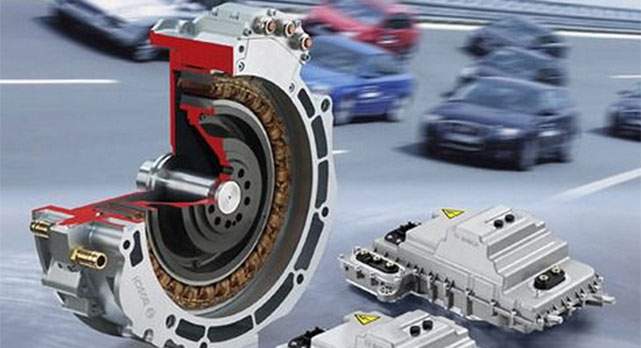

![[New energy] - electric motor principle](/upload/image/20170519/20170519090819_74516.jpg)