1. Check the preparation before installation

Before installation, the supervision engineer and the engineer of Party A should check whether the access road is unblocked. If necessary, the general contractor is required to construct a simple transportation passage to connect with each installation point. The layout of the construction site should meet the requirements of safe and civilized construction. At the same time, the construction equipment of the installation unit should be inspected and the installation unit should be inspected to ensure that the construction equipment is in good condition. Before the high-voltage equipment arrives at the site, the power distribution room, trench, and foundation channel steel should be completely completed.

1), distribution room

Power distribution room: Before the construction of the power distribution room, the detailed drawings required for the construction of the power distribution room shall be handed over to the construction party (within 2 weeks after the contract is signed, the key points shall be to implement the customer's confirmation of the location, content and completion time of the drawings), and During the construction of the power distribution room, the technical personnel of our or the cooperative unit shall supervise on site to avoid construction errors. (The construction of the power distribution room takes about 2 weeks)

2) Foundation: The location of the channel steel should correspond to the air duct of the equipment reserved in the power distribution room. The minimum distance from the wall should be clear (the distance is too close, and the door of the equipment cannot be opened). (The channel welding takes about 2 days, and our technicians must be present to guide)

The equipment arrives at the scene:

3) If the power distribution room and foundation are not built, the equipment should have a storage location (to prevent rain or provide necessary rainproof materials).

2. Installation

2.1 The doors and windows of each power distribution room shall be tight and the room shall be clean.

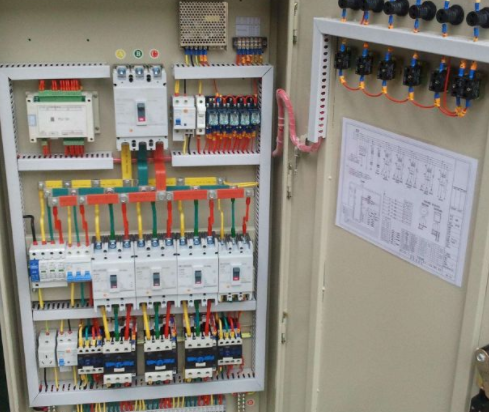

2.2 The switchboard is installed securely. The equipment inside the disc is firmly connected to each component.

2.3 The grounding of the disk and cabinet should be firm and good. Openable discs and cabinet doors with electrical appliances shall be reliably connected to the grounded metal frame by flexible conductors.

2.4 The terminal box should be installed firmly and well sealed. The installation position should be easy to check. When installing in a row, it should be arranged neatly.

2.5 The wiring inside the switchboard should be horizontal and vertical, the screws should not be loose, and the wire ends should be in good contact.

2.6 The components in the disc are fixed and reliable without looseness, and the contacts are not oxidized and have no burrs.

2.7 The connection of the secondary circuit shall be made of copper. Specific requirements for the knot:

2.7.1 The connection of electrical circuits (bolt connection, plugging, welding, etc.) should be firm and reliable.

2.7.2 The end of the cable core wire and the wire to be fitted shall be marked with the circuit number; the number shall be correct, the writing shall be clear and the color shall not be discolored.

2.7.3 The wiring is neat, clear and beautiful; the wire is well insulated and has no damage.

2.7.4 There should be no connectors for the wires in the disk and cabinet.

2.7.5 The wiring on each side of each terminal block is generally one, not more than two.

2.8 The electrical gap between the electrified bodies of the secondary circuit of 400 volts and below or between the charged body and the ground shall not be less than 4 mm. The leakage distance should not be less than 6 mm.

2.9 The wires used for connecting the movable parts (door appliances, console boards, etc.) should meet the following requirements:

2.9.1 Multiple strands of flexible conductors shall be used and shall have appropriate margins for laying.

2.9.2 Harness should be reinforced insulation layer (such as jacket plastic tube, etc.).

2.9.3 When connecting with electrical appliances, the ends should be tightened, not loose, and stranded.

2.9.4 At both ends of the movable part, the clamp is fixed.

2.10 The control cables and their core wires in the introduction trays and cabinets shall meet the following requirements:

2.10.1 The cables for the introduction of disks and cabinets shall be neatly arranged to avoid crossover and shall be fixed firmly so as not to subject the connected terminal plates to mechanical stress.

2.10.2 The steel strip of the armored cable shall not enter the disc or the cabinet; the end of the cut-off portion of the armored steel strip shall be tightened;

2.10.3 For the control cable of transistor protection, control and other logic loops, when shielded cable is used, its shielding layer should be grounded; if shielded cable is not used, the base spare core should have a grounding;

2.10.4 The rubber insulated core wire shall be protected by a jacket insulation tube;

2.10.5 The cable core wire in the disk and cabinet shall be regularly or horizontally arranged, and shall not be arbitrarily skewed and cross-connected; the spare core shall have appropriate margin.

2.11 Where the insulated conductor may be contaminated by oil, oil-resistant insulated conductors shall be used or oil-proof measures shall be taken.

2.12 Safety technical requirements for power distribution equipment:

2.12.1 When two or more power supplies are supplied, an interlock device shall be installed between the main power inlet and the tie switch (except for the dispatcher of the power supply department).

2.12.2 Interlocking devices shall be installed between the isolating switch of the 10 kV indoor unit and the corresponding circuit breaker.

2.12.3 The phase arrangement of the power distribution device shall comply with the requirements of the column:

(1) The color arrangement of each circuit in the same power distribution device should be as consistent as possible.

(2) The hard busbar should be painted, and its color is: a phase yellow; b phase green; c phase red;

(3) The soft busbars should be marked with the same.

(4) The conductors in the interval of the power distribution device shall be left with the position where the temporary grounding wire is suspended. No phase lacquer shall be applied here.

2.13 Terminal board installation should meet the following requirements:

2.13.1 The terminal board shall be free of damage, securely fixed and well insulated.

2.13.2 Terminal boards should be easy to replace and convenient to wire.

2.13.3 Where the loop voltage exceeds 400 volts, the terminal block shall be sufficiently insulated and marked with a red mark.

3 check

3.1 inspection

3.1.1 Whether the ventilation, lighting and safety fire protection devices of the high and low voltage distribution rooms are normal.

3.1.2 The switchboard door is tight and has no damage. The switchboard is clean and free of dust.

3.1.3 All power distribution panels in the station must be listed for warning.

3.1.4 The signal light, electric bell, accident electric clock, etc. of the signal device circuit should be displayed accurately and work reliably.

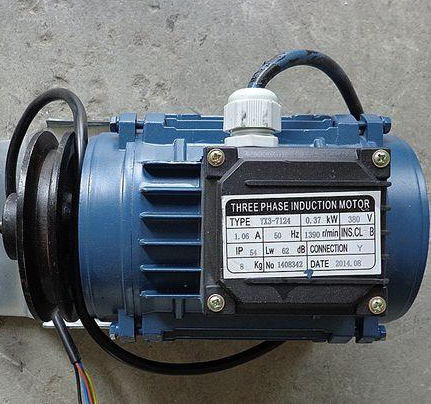

3.1.5 Whether the voltage and current of the motor in the power distribution cabinet are normal (not exceeding 5% of the rated value).

3.1.6 Whether the busbar and each contact have overheating phenomenon, whether the temperature wax sheet is melted, and whether the insulating bakelite is burnt or not.

3.1.7 Whether the electrical components in the switchgear have abnormal smell and sound during operation.

3.1.8 Is the oil level of the oil filling equipment normal, whether the oil color is deep, and whether there is leakage oil.

3.1.9 Whether the indications of the instrument, signal, indicator light, etc. are correct, and the position of the relay protection platen is correct.

3.1.10 Relay and DC equipment are running well.

3.1.11 Whether the connection line of the grounding and zeroing device is loose or broken.

3.1.12 Whether the insulation of porcelain bottles, insulating sleeves and wall bushings is clean, with or without damage cracks and discharge marks.

3.1.13 Is the mechanical interlock of the circuit breaker and the isolating switch flexible and reliable? If electromagnetic interlocking device is used, it is necessary to check whether the electromagnetic lock is flexible and whether the opening and closing is accurate.

3.2 month check

Monthly inspection of each operating part and electrical part of the motor and power distribution cabinet, magnetic starter dynamic closing test, and relay sensitivity test.

3.3 annual inspection

Every three years, a relay test is performed on the motor and the power distribution cabinet, which is verified by the power supply personnel.

3.4 Inspection and maintenance

3.4.1 Inspection and maintenance are carried out once a month.

3.4.1 The power outage maintenance line must be listed first and then operated to show the warning.

3.4.2 The motor, cable and power distribution panel must be well grounded, and the grounding resistance should not exceed 4 ohms.

3.4.3 Motor measures DC impedance for AC withstand voltage test. Current transformers and voltage transformers are used for withstand voltage test and converter ratio test.

3.4.5 Cable for DC withstand voltage leakage test; relay overhaul, re-setting.

3.4.6 Oil switch for disassembly inspection, repair, adjustment, and fastening; arrester for pressure test.

RCCN WeChat QrCode

RCCN WeChat QrCode Mobile WebSite

Mobile WebSite