1. You should fully understand the cold-pressed terminals to be operated, familiar with the operation methods to ensure correct operation; for cold-pressed terminals that do not have anti-misoperation, they should be marked with color code or symbol, or whether the appropriate model should be matched before the connection And ensure correct positioning when connecting each other; special attention should be paid to avoid mis-insertion of the pin socket, otherwise the cold-pressed terminal will be damaged and an accidental electric touch will be caused; the cold-pressed terminal should be connected to the position, in special occasions that are difficult to view, Specific rules are made in the corresponding operating procedures and can be viewed through the scope.

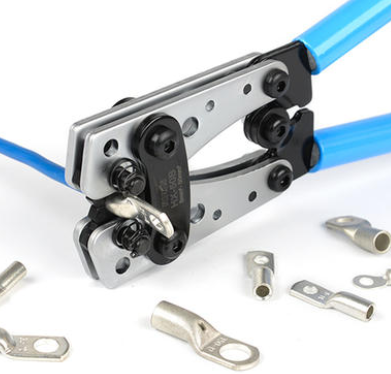

Cold-pressed terminal block

2. When the cold-pressed terminal is terminated, it should be terminated and viewed in strict accordance with the corresponding termination specifications or requirements, and terminated according to the corresponding node serial number. The maximum insulation thickness between the selected cable conductors should be matched with the distance of the touched parts. The cable core should be matched with the touch terminal, and the touch parts should be crossed and lined.

3. When soldering, the soldering iron of the corresponding power should be selected according to the diameter of the bare wire. The soldering time of each touch component generally does not exceed 5S. It should be noted that the solder should not enter the insulator and avoid the drop of the insulation resistance of the product.

4. If the cold-pressed terminals are in a different position, do not leave the maintenance cap or adopt other dust-proof methods; if the cold-pressed terminals are connected for a long time, they can be safely connected between the plug and the socket.

5. When cleaning the cold-pressed terminal block, it can be used with silk cloth with absolute ethanol, and dried after drying. Chemical solvents such as acetone, which may have a detrimental effect on the adapter, are not permitted.

6. When the cold-pressed terminals are connected or separated, the shaft wires of the plug and the socket should be overlapped as much as possible, and the cable should be straightened to avoid the tangential force of the plug, so as to avoid the damage of the connector caused by the cable sag.

7. The cold-pressed terminal stops the power supply before it is properly connected or completely locked, so as to avoid problems!

8. In the case of fixing the cold-pressed terminal, clamping of the wire harness, etc., there should be anti-loose equipment (anti-loose screw, anti-loose ring, stable wire, etc.) when using the thread connection.

RCCN WeChat QrCode

RCCN WeChat QrCode Mobile WebSite

Mobile WebSite