Beginning in 2010, on the fertile soil provided by the national industrial policy, the growth of the new energy automobile industry is in full swing, bringing innovative changes to the development of China's automobile industry. At the same time, due to the service life (5 to 8 years), electric vehicle power batteries will usher in the retreat in the past two years.

While opportunities and challenges coexist, the construction of a power battery recycling system is imminent.

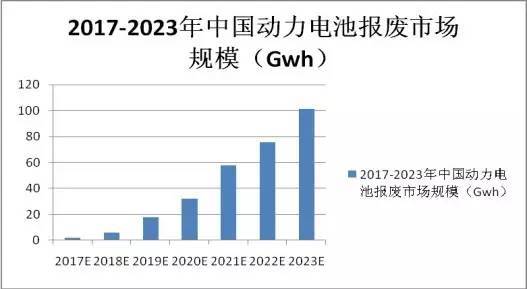

By 2020, power battery scrap recycling will usher in a large-scale growth period

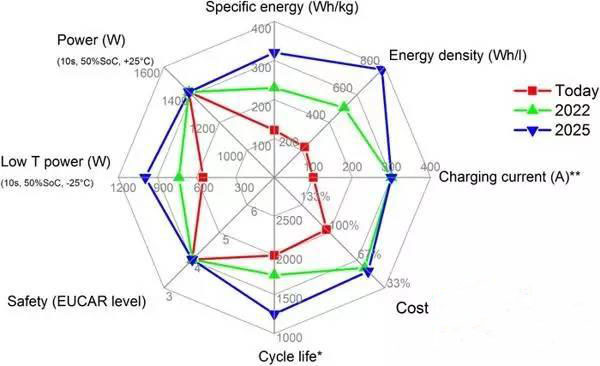

According to industry-related data, with the rapid development of the new energy auto industry, China's power lithium battery scrap will reach 32.2 Gwh, about 500,000 tons by 2020; by 2023, the scrap will reach 101 Gwh, about 1.16 million tons. .

“The industry generally believes that by 2020, the recycling of power batteries will surely usher in a large-scale growth period,” said Hancheng, general manager of Hao Peng Technology. “This is also the current capital in addition to car companies, battery companies, and raw material recycling companies. The reason for entering the battery recycling market."

In addition, the economics of lithium battery recycling is not to be underestimated. With the expansion of the power battery recycling market and the trend of battery materials, the prices of cobalt, nickel and lithium carbonate/lithium hydroxide have been boosted to some extent. According to industry data, the metal content of different types of power batteries is different. According to the estimation of the scrap quantity of lithium-ion batteries in China in the future, by 2023, the market value of recoverable valuable metals can reach: 7.3 billion yuan of cobalt, nickel 8.4 billion yuan, lithium 14.6 billion yuan, manganese 850 million yuan.

For a time, power battery recycling seems to be a new vent.

Imperfect system, safety and environmental protection

But unfortunately, there are still many difficulties in battery recycling in China.

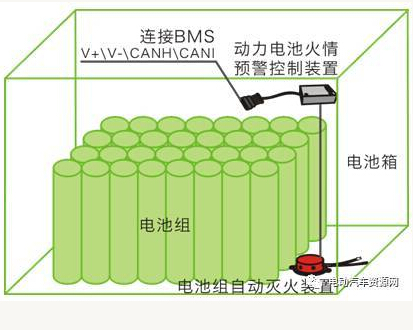

It is understood that the types of batteries that are selected and configured by different car manufacturers are not the same, which has become the first major problem in the process of recycling and dismantling of battery recycling enterprises. “The technical standards of each battery company are not unified. Before reuse, it is difficult to detect and increase the risk of re-use,” experts said.

"Secondly, the domestic power battery recycling technology is not comprehensive enough, and the recycling cost is relatively large. This makes it easy to form a situation of high investment and insufficient output."

It is also worth noting that some unqualified enterprises recycle the used batteries and arbitrarily dispose of the used batteries by methods that do not meet the requirements, resulting in serious environmental pollution. With the continuous strengthening of environmental protection supervision, such unqualified recycling enterprises have been shut down one after another, which has gradually narrowed the recycling channels of batteries and the chaos of the price system.

So in this context, is the recovery of power batteries an opportunity or a challenge?

“The challenge is greater than the opportunity”, Li Yuke, director of the Automotive Industry Policy Research Office, told the first electric network that “battery recycling is first of all a safety and environmental issue, and secondly how to use the residual value of the old battery. At present, I think the complete standard power battery The construction of the recycling system has not yet been formed. Whether the automobile production enterprise is the main body of responsibility for building a recycling system has become the real mainstream channel for the recycling market, and whether it can cope with the safety and environmental protection pressure brought by the batch scrapping of batteries, remains to be seen."

The upstream and downstream of the industrial chain need to work together

In fact, while national policies provide fertile ground for the growth of car-making forces, they have never neglected the construction of battery recycling systems.

In 2012, the State Council issued the "Energy Conservation and New Energy Vehicle Industry Development Plan (2012-2020)" stipulates: It is necessary to formulate management measures for power battery recycling and utilization, and establish a power battery cascade utilization and recycling management system; in 2014, the State Council Office The "Guiding Opinions on Accelerating the Promotion and Application of New Energy Vehicles" states: It is necessary to study and formulate policies for recycling and utilization of power batteries, and establish and improve a recycling system for used power batteries. Since 2016, the Ministry of Industry and Information Technology has issued three documents to clarify the main body of waste battery recycling, and also strengthened industry management and recycling supervision.

Li Yuke told the first electric network: "The domestic power battery recycling system is in the early stage of establishment. The relevant departments have issued policies requiring automobile manufacturers to build power battery recycling service outlets, and jointly build upstream power generation enterprises, downstream recycling enterprises and scrap car dismantling enterprises. Battery recycling system, some car companies (such as BYD, Beiqi New Energy) have announced their own power battery recycling service outlets. At the same time, the Ministry of Industry and Information Technology has established a power battery traceability information system, requiring full life cycle traceability of power batteries, and strive to ensure The waste power battery generated in each link can be traced back. In terms of cascade utilization, enterprises have carried out demonstration test work in the fields of backup power supply and energy storage of communication base stations. In terms of recycling, a group of enterprises have built physical battery physical disassembly and wet method. Recycling production line."

"The signing of the letter of intent can be seen as an important step in the construction of China's power battery recycling system and the use of cascades." Li Yuke said frankly.

Finally, Li Yuke said that the establishment of the power battery recycling system, in addition to the joint efforts of upstream and downstream enterprises in the industry chain, requires efforts in the following areas: First, the introduction of mandatory regulations for the recycling of power batteries, set up recycling from environmental protection and safety. Take advantage of the company's entry barriers; second, strictly enforce the law enforcement, impose penalties on enterprises and individuals who illegally hand over and sell power batteries; third, introduce preferential taxation systems for environmentally-friendly recycling enterprises, so that regulated recycling enterprises can carry out environmental protection normally. Recycling activities; Fourth, the media to strengthen publicity, enhance consumer safety and environmental awareness, and promote the transfer of used batteries to consumers through formal recycling channels.

RCCN WeChat QrCode

RCCN WeChat QrCode Mobile WebSite

Mobile WebSite