Servo system is an important part of electromechanical products, it can provide the highest level of dynamic response and torque density, so the development trend of the drag system is to replace the traditional hydraulic, DC, step and AC variable frequency drive with AC servo drive. In order to bring system performance to a whole new level, including shorter cycle times, higher productivity, better reliability and longer life. In order to achieve better performance of the servo motor, it is necessary to understand some of the characteristics of the servo motor. This article will analyze the common problems of servo motors in use.

Noise, instability

When some users use servo motors on some machines, the noise is too large, and the motor drives the load to run unstable. When this problem occurs, the first reaction of many users is that the quality of the servo motor is not good, because sometimes it is changed. As a stepper motor or a variable frequency motor to drag the load, the noise and instability are much smaller. On the surface, it is indeed the reason of the servo motor, but after careful analysis of the working principle of the servo motor, we will find that this conclusion is completely wrong.

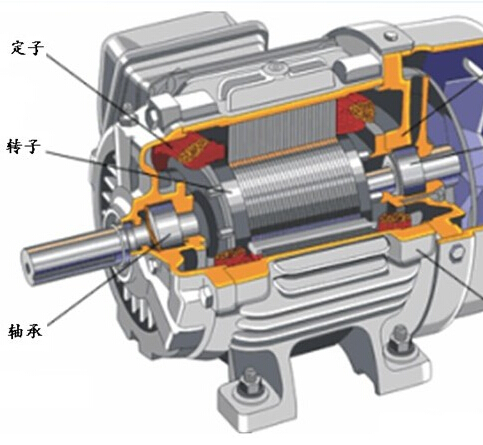

The AC servo system includes: servo drive, servo motor and a feedback sensor (general servo motor comes with an optical encoder). All of these components operate in a controlled closed-loop system: the drive receives parameter information from the outside, and then delivers a certain current to the motor, which is converted into torque-driven load by the motor. The load acts or accelerates and decelerates according to its own characteristics. The sensor measures the load. The position of the drive device compares the set information value with the actual position value, and then the actual position value and the set information value are kept consistent by changing the motor current. When the load suddenly changes to cause a speed change, the digitizer knows this. After the speed changes, it will react to the servo drive immediately. The drive will change the value of the current supplied to the servo motor to meet the load change and return to the set speed. The AC servo system is a very high-response full-closed system. The time lag response between load fluctuation and speed correction is very fast. At this time, the real response to the system response is the transmission time of the mechanical connection device.

RCCN WeChat QrCode

RCCN WeChat QrCode Mobile WebSite

Mobile WebSite