Since the development of electric vehicles, we are very concerned about the problem is its high security is not high? Around the organization of the Summit Forum, should be related to the discussion of battery safety. Lithium-ion battery is safe? Is the electric car safe? Many experts speech, the 2015-2016 two years of electric vehicles, especially bus passenger safety examples were statistics, both Tesla, but also the domestic manufacturers of electric vehicles occurred in the incident. These events are real, so some experts have concluded that China's electric vehicles are unsafe, mainly because lithium-ion batteries are unsafe. The author's point of view is that security measures in place, electric cars are safe, otherwise it is not safe.

This article is based on the electric car is based on the traditional car, the following discussion is based on the traditional car safety measures have been able to protect their safety under the premise of the discussion of electric vehicle safety technology and measures.

First, lithium-ion battery is safe, is the basis of what is green?

Lithium cobalt oxide, lithium manganese oxide and lithium iron phosphate cathode material inventor, one of the founders of lithium-ion battery, the industry known as the "father of lithium", the current University of Texas at Austin, Professor of Mechanical Engineering, John B. Goodenough, a well-known solid-state physicist, said: "The battery will make significant improvements over the next few years, including battery safety, price, energy density, Life, charge and discharge speed.

I understand that the next few years, lithium-ion battery will become increasingly safe. At present, lithium-ion battery is safe, is the main basis for the green is:

(1) Lithium-ion batteries and steam (diesel) oil, compared with natural gas, in natural (normal) conditions, will not spontaneous combustion, no leakage.

(2) compared with lead-acid batteries, in the natural (normal) conditions, the air, no pollution to the soil.

Some experts have repeatedly stressed that lithium-ion battery is not safe, not green. That is beyond the "natural (normal) conditions" circumstances may occur in the event. For example, the battery quality is poor, by external combat, charge (release) electric transition and other extreme scenarios.

Second, China's electric car is safe, is the main basis for environmental protection is what?

(1) China's electric vehicles (new energy vehicles) must use lithium-ion batteries, shall not use lead-acid batteries. Ordinary people on the lead-acid battery is not environmentally friendly understanding and understanding.

(2) China's electric vehicles (new energy vehicles) regulations must be "pure electric drive" mode. Lithium-ion batteries are epoch-making scientific inventions. China's pure electric vehicles use the power of the category and the world's scientific and technological progress is synchronized.

(3) electric vehicle manufacturers to purchase lithium-ion battery, the manufacturers are licensed by the manufacturers, the quality of their products is good or bad, there is a government endorsement, the government power battery manufacturers are strictly controlled.

(4) China's electric car is a lithium-ion battery, its safety, environmental protection, which is relative to the fuel (gas) car in terms of.

Third, the Chinese power battery pack product quality (security) progress with each passing day

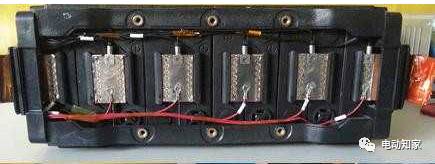

5 years ago, electric vehicle production is a small batch, vehicle production technology is not mature, focusing on the application of the project validation, in the market validation stage. It can be seen from Fig. 1 that the wiring harness of the battery pack is relatively simple. The wire extends the pole measuring point to the connector and is connected with the LECU by the connector. Sampling harness length, patch point. There is a sampling harness messy, harness wear short circuit will have the risk of short circuit.

Figure 1 Five years ago the power battery pack

5 years later, electric car production began on the batch, the vehicle production technology is basically mature, focusing on the market heavy volume stage. Component modularity is already high. Mainly by the Module, BMU, PDU, water cooling system, MSD, structural parts, high and low voltage wiring harness, using a circuit board instead of part of the sampling line.

Figure 2 Five years after the power battery pack

Fourth, China's pure electric vehicle main high-voltage device quality (safety) technology

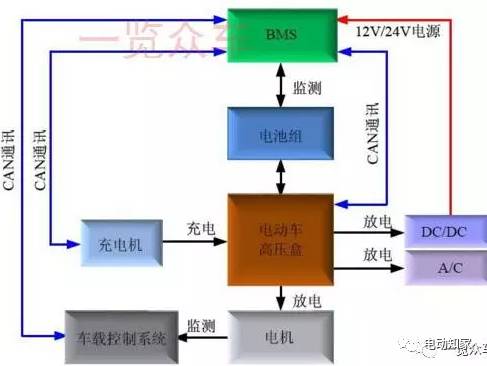

The following is a pure electric vehicle high voltage system schematics, from the schematic diagram, the main high-voltage devices are battery pack, high voltage box, motor, DC / DC, A / C and other five high-voltage devices. From the project, the quality of high-voltage devices and the quality of each other to do a good job, the safety of electric vehicles can be guaranteed. Safety indicators continue to enhance the eternal issues, specific issues, and then specifically explore.

Figure 3 pure electric vehicle high pressure system schematic diagram

Electric vehicles are usually equipped with more than 300V and current up to 200A power system. This is only with the traditional car with 12 / 24V power supply system, the security level is completely different. Electric vehicles of this high voltage and high current characteristics, may endanger the use of high-pressure parts safety and personal safety. From the project, the security measures must be done in place, the following were introduced:

(1) high-voltage distribution box security technology

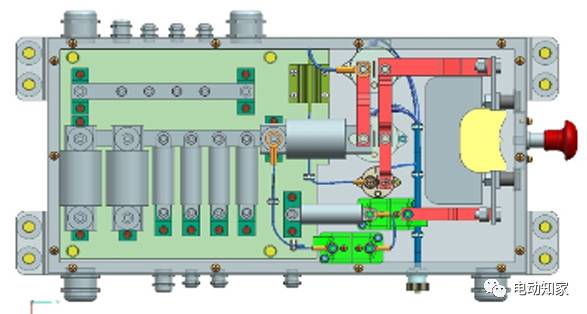

Figure 4 high voltage distribution box shape and internal structure

Those who have business experience know that every factory has a distribution room. A car compared to a factory, high-voltage distribution box (see Figure 4) is the factory power distribution room. Electric vehicle high voltage box (PDU) function is the power battery and the high voltage equipment, power and signal transmission bridge, and at any time to detect the entire high voltage system insulation fault, fault, ground fault and high voltage fault, is the vehicle system power Safe transmission of security measures.

Pure electric vehicle high voltage distribution box inside the copper, circuit breakers, air open, contactors, soft start, inverter, transformers, contactors, high voltage relays, fuses, surge protector, transformer, ammeter, voltmeter , Transfer switches and so on.

A) The basic purpose of the design of high-voltage distribution box: to ensure the safety of the car, occupant safety and safety of the vehicle operating environment.

B) the need for the design of high-voltage distribution box: power battery as an electric vehicle energy storage device, by the vehicle size is small, the space is very limited, and the difficulty of the layout, so the project, the circuit contactors and fuses And so on, on the one hand to meet the vehicle power drive requirements, the second is to facilitate the maintenance of power battery system to reduce the need to remove the power battery pack.

C) high voltage distribution box design requirements: device layout is compact, easy to disassemble and assembly

D) safety measures are, pay attention to heat layout, to prevent the temperature rise.

High voltage components connected with the high voltage distribution box include: power battery, motor controller, inverter, inverter power supply, electric air conditioning, electric defrost, charging seat and so on. At present, the general use of cast aluminum shell and connectors, protection level to IP67 level. Subsequent development trend is, toward the small size, lightweight, intelligent direction.

(2) high-voltage connectors and high-voltage wire harness security measures

Conventional connector equipment has been difficult to meet its high current, high voltage requirements, electric car connector must be high-power connection products. If not meet the requirements of the electric car accident occurred in the inevitable. The electric car connector must be an automotive grade product, and the industrial grade product is not required. The main indicators are IP level, insulation level, low resistance, error-proof, lock function.

Figure 5 different specifications of the high-voltage connector

The wiring harness is a component in which the contact terminal (connector) made of copper is crimped with the electric wire (cable), and the outer wire is wrapped with a plastic pressure insulator or an outer metal case, and the wiring harness is bundled to form a connecting circuit. From the function point, there are two types of power lines that carry the drive actuator (actuator) power and the sensor input signal. Power line is divided into low-voltage wiring harness (see Figure 5) and high-voltage wiring harness (see Figure 7) two.

Figure 5 low-voltage automotive wiring harness

The high-voltage wire harness is the cable between the connector and the connector inside the electric vehicle and is a very critical connection that supports the safe operation of the entire vehicle. One is required to shield, there are IP level, anti-overheating or burning, car use is the environment is bad, if not meet the requirements, is the most prone to spontaneous combustion components.

Figure 6 automotive high-voltage wiring harness

Fifth, ISO26262 international standards under the guidance of China's electric car will become increasingly safe

ISO26262 positioning in the automotive industry in the specific electrical devices, electronic equipment, programmable electronic devices specifically for the automotive field of electronic, electrical products, functional safety international standards. ISO 26262 provides a lifecycle (management, development, production, operation, service, scrapping) concept for automotive safety and provides the necessary support during these lifecycle phases. This standard covers the overall development process (including requirements planning, design, implementation, integration, validation, validation and configuration) of functional security.

With the development of new energy vehicles in China, the manufacturers of the technical level is getting higher and higher, through the active implementation of ISO26262 international standards, China's new energy vehicle safety ecosystem will form, people worry about the safety of electric vehicles will be gradually eliminated. Source: First electric network

RCCN WeChat QrCode

RCCN WeChat QrCode Mobile WebSite

Mobile WebSite